– 7 –

The appliance must be isolated from the gas supply

piping system by closing it’s individual manual

shutoff valve during any pressure testing of the gas

supply piping system at test pressure equal to or

less than 1/2 PSIG.

Correctly sized piping must be run to the unit.

Please note that gas line pressure must be

as shown on specifi cation plate when unit is

operating at full input. The high-pressure regulator

and relief valve should be, if possible, mounted

at least 5 to 10 feet upstream from the appliance

regulator on the unit (if possible).

Building Pressure Transducer Piping (PT-13)

Pipe the high side to location inside the building that

will not be affected by air movement. Pipe the low side

to the atmosphere, positioned so it will not be affected

by the wind and not exposed to the elements. Be sure

that all tubing is clean and clear of any debris before

installing tubes on the transducer.

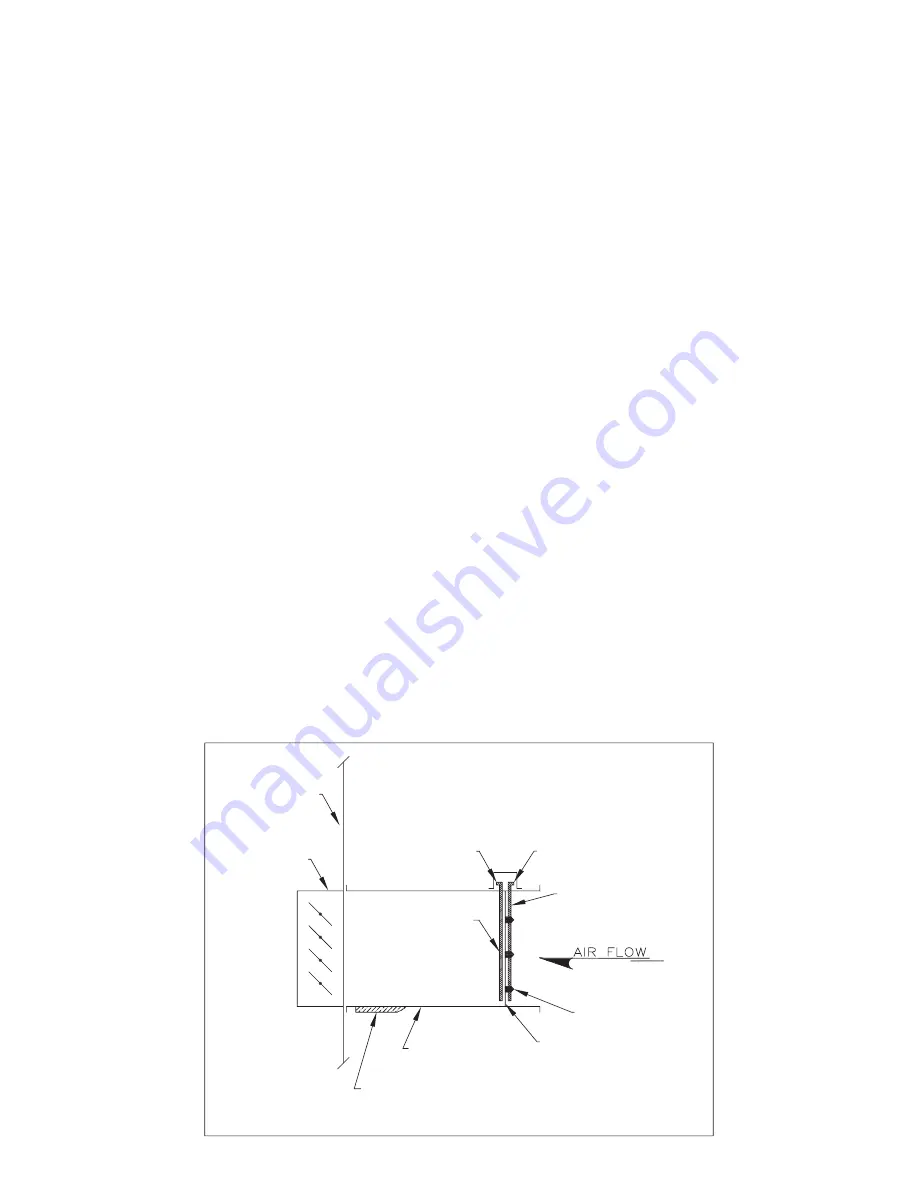

Flow Station Transducer Piping (PT-15)

Pipe the high side to the upstream connection and

low side to the downstream connection of the Air

fl

ow

Station as shown in Drawing # C000643 below. Be

sure that all tubing is clean and clear of any debris

before installing tubes on the transducer.

G. Field Wiring and Remote Control Installation

1. Connect the power lines to the line side of

the power distribution block or optional main

disconnect switch.

2. Field wiring is typically indicated on the wiring

diagram as dashed lines. When running any

fi

eld

wiring for control circuit be sure wire is sized for

a maximum 10% voltage drop. Check the VA

rating of control circuit transformer to determine

maximum load.

3. Mount and wire remote control panel, thermostats,

temperature sensors, and any other

fi

eld installed

controls as indicated on the unit control wiring diagram.

4. Connect all wires to the appropriate

fi

eld wiring

terminals and any shielded or twisted wires as indicated

on the unit control diagram.

5. Field wiring shall have a temperature rating of at

least 105°C. The minimum size of the supply cable

circuit shall be suf

fi

cient for the maximum ampacity

of the heater.

L'installation éléctrique d'utilisateur aura une

température qui évalue d'au moins 105°C. La

minimum de source du circuit de câblage sera

suf

fi

sante pour le ampacity maximum de l'appareil

de chauffage.

H. Locating Temperature Controls

The room or outdoor sensors should be mounted

where they will not be subjected to direct impact of

the heated air or radiant heat from the sun. It is also

recommended that thermostats, especially those with

mercury bulb contacts, be mounted on a vibration free

surface. The side of building columns away from the

heater or interior walls are usually the location best

suited for mounting thermostats.

Controls with outdoor sensors require that the outdoor

sensor be shielded from direct radiation from the sun. Unit

mounted sensors are factory located and mounted.

AMPLIFIER WING

(SHEET METAL STRIP)

TOTAL PRESSURE

SENSING TUBE

BULLET

STATIC PRESSURE

SENSING TUBE

HIGH PRESSURE

TUBE CONNECTION

LOW PRESSURE

TUBE CONNECTION

AIRFLOW STATION LAYOUT

C000643

AIRFLOW STATIO N

EXTERIOR INSULATION

FIELD PROVIDED WHEN

MOUNTED OUTDOORS

RA DAMPER

HEATER

CASING

NOTE: RUN TUBE CONNECTIONS

TO TRANSDUCER (PT-15) IN

UNIT CONTROL ENCLOSURE