1

HT-6E-CIA-FS

SUBMERSIBLE

EFFLUENT PUMP

INTRODUCTION

This instruction sheet provides you with the information required to

safely own and operate your product. Retain these instructions for

future reference.

The product you have purchased is of the highest quality

workmanship and material, and has been engineered to give you

long and reliable service. This product has been carefully tested,

inspected, and packaged to ensure safe delivery and operation.

Please examine your item(s) carefully to ensure that no damage

occurred during shipment. If damage has occurred, please contact

the place of purchase. They will assist you in replacement or repair,

if required.

READ THESE INSTRUCTIONS CAREFULLY BEFORE

ATTEMPTING TO INSTALL, OPERATE, OR SERVICE

YOUR PRODUCT. KNOW THE PRODUCT’S APPLICATION,

LIMITATIONS, AND POTENTIAL HAZARDS. PROTECT

YOURSELF AND OTHERS BY OBSERVING ALL SAFETY

INFORMATION. FAILURE TO COMPLY WITH THESE

INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/

OR PROPERTY DAMAGE!

DESCRIPTION

This is a submersible effluent pump for use in basins or lift stations,

and is suitable for pumping effluent, wastewater, and other non-

explosive, non-corrosive liquids with up to 1/2” spherical solids and

temperatures up to 200°F.

SAFETY GUIDELINES

CAUTION: INTENDED FOR COMMERCIAL AND INDUSTRIAL

USE ONLY. READ SAFETY GUIDELINES AND INSTRUCTIONS

CAREFULLY.

1. Do not use to pump flammable or explosive fluids such as

gasoline, fuel oil, kerosene, etc. Do not use in explosive

atmospheres or hazardous locations as classified by NEC,

ANSI/NFPAT. Pump should only be used with liquids compatible

with pump component materials.

2. Do not handle pump with wet hands or when standing on a wet

or damp surface, or in water.

3. Do not pull the pump out of the water by the power cord when

the pump is operating or connected to power source.

4. This pump is supplied with a grounding conductor and/or

grounding type attachment plug. To reduce the risk of electric

shock, be certain that it is connected to a properly grounded

grounding type receptacle.

5. The National Electric Code requires a ground fault circuit

interrupter (GFCI) be installed in the branch circuit supplying

fountain equipment, pools, etc.

6. In any installations where property damage and/or personal

injury might result from an inoperative or leaking pump due to

power outages, discharge line blockage, or any other reason, a

backup system(s) and/or alarm should be used.

7. Support pump and piping when assembling and when installed,

failure to do so may cause piping to break, pump to fail, motor

bearing failures, etc.

8. This pump’s motor housing is filled with a dielectric oil for motor

heat transfer and life-time lubrication of the bearings. This oil is

non-toxic to aquatic life, however, suffocation can occur if oil is

left on the water surface. If oil escapes the motor housing, it can

be removed from the surface quickly by placing newspapers on

the water surface to soak up the oil.

9. The pump motor is equipped with an automatic resetting thermal

protector and may restart unexpectedly. Protector tripping is an

indication of motor overloading as a result of excessively high or

low voltage, inadequate wiring, incorrect motor connections, or

a defective motor or pump.

ELECTRICAL CONNECTIONS

1. Check the pump label for proper voltage required. Do not

connect to voltage other than that shown.

2. If pump is supplied with a 3-prong electrical plug, the third

prong is to ground the pump to prevent possible electrical

shock hazard. DO NOT REMOVE the third prong from the plug.

A separate branch circuit is recommended. Do not use an

extension cord.

3. If the cord is equipped with stripped lead wires, such as on 230V

models, be sure that the lead wires are connected to a power

source correctly. The green/yellow wire is the ground, the other

two are live.

4. Check local electrical and building codes before installation.

The installation must be in accordance with their regulations as

well as the most recent National Electrical Code (NEC).

5. To conform to the National Electrical Code, all pumps must be

wired with 14 AWG or larger wire. For runs to 250 feet, 14 AWG

wire is sufficient. For longer runs, consult a qualified electrician

or the factory.

6. Pump should be connected or wired to its own circuit with no

other outlets or equipment in the circuit line. Fuses and circuit

breaker should be of ample capacity in the electrical circuit.

Franklin Electric Co., Inc.

P. O. Box 12010

Oklahoma City, OK 73157-2010

405.947.2511 • Fax: 405.947.8720

www.LittleGiantPump.com

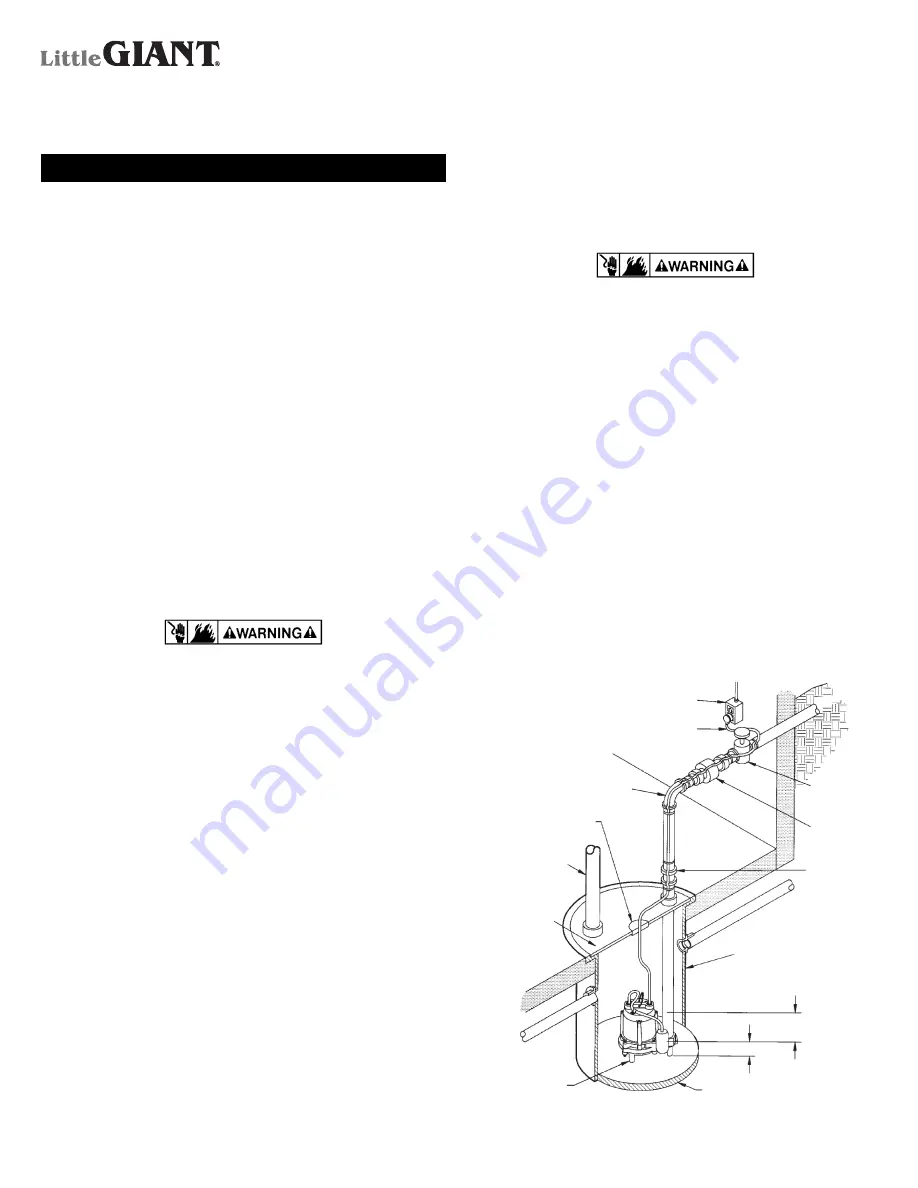

Discharge pipe no smaller than pump outlet

Power Cord Grommet

2" or 3" Vent Pipe

Basin Cover

Pump

Union

Check Valve

Gate Valve

Place pump on hard level surface. Never place

directly on clay, earth or gravel surface.

11"–14" on level

3"–6" off level

Gas Tight Basin 18" dia. x 24" deep min.

Separate protected and grounded service outlet 4' from floor min.

Pump Power Cord

Figure 1