INTRODUCTION

EN

This instruction sheet provides you with the information required to safely own

and operate your product. Retain these instructions for future reference.

The product you have purchased is of the highest quality workmanship and

material, and has been engineered to give you long and reliable service. This

product has been carefully tested, inspected, and packaged to ensure safe

delivery and operation. Please examine your item(s) carefully to ensure that no

damage occurred during shipment. If damage has occurred, please contact the

place of purchase. They will assist you in replacement or repair, if required.

READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING

TO INSTALL, OPERATE, OR SERVICE YOUR PRODUCT. KNOW THE

PRODUCT’S APPLICATION, LIMITATIONS, AND POTENTIAL HAZARDS.

PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY

INFORMATION. FAILURE TO COMPLY WITH THESE INSTRUCTIONS

COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE!

DESCRIPTION

This pump is recommended for use in basins or lift stations and is suitable for

pumping sewage, effluent, wastewater, and other non-explosive, non-corrosive

liquids. It can handle 2” spherical solids.

Little Giant offers a complete line of control systems, along with a complete line

of alarms, basins, covers, and check valves.

SPECIFICATIONS

Discharge Size:

3”

FNPT

Handling Capabilities:

S Series: 2” spherical solids

Pump Housing:

Cast

iron

Volute:

Cast

iron

Impeller:

Non-clog brass with pressure relief vanes

Motor:

3-phase, 3200 RPM (control panel required)

Hardware:

300 Series stainless steel

Bearing:

Ball

Shaft Seal:

Mechanical, spring loaded, rotating carbon with Nitrile

boot and stationary ceramic seat, with secondary Nitrile

exclusion seal

Power Cord:

14 AWG 4-conductor, copper, stranded

Cooling:

The motor housing contains a cooling oil to provide

cooling for the motor and to lubricate bearings and

seals. These pumps are capable of operating with the

motor housing partially exposed for extended periods

of time, providing sufficient motor cooling and bearing

lubrication. However, for the best cooling and longest

motor life, the liquid level being pumped should normally

be above the top of the cast iron motor housing.

SAFETY GUIDELINES

WARNING: RISK OF ELECTRIC SHOCK.

THIS PUMP IS SUPPLIED WITH A

GROUNDING CONDUCTOR. TO REDUCE THE RISK OF ELECTRIC SHOCK,

BE CERTAIN THAT IT IS CONNECTED TO A PROPER ELECTRICAL GROUND.

DO NOT REMOVE CORD OR STRAIN RELIEF. DO NOT CONNECT CONDUIT

TO PUMP. THIS PUMP MUST BE INSTALLED BY QUALIFIED PERSONNEL.

1. Read all instructions and Safety Guidelines thoroughly. Failure to follow the

guidelines and instructions could result in serious bodily injury and/or property

damage.

2. DO NOT USE TO PUMP FLAMMABLE OR EXPLOSIVE FLUIDS SUCH

AS GASOLINE, FUEL OIL, KEROSENE, ETC. FAILURE TO FOLLOW

THIS WARNING CAN RESULT IN PERSONAL INJURY AND/OR PROPERTY

DAMAGE.

3. During normal operation the pump is immersed in water. Also, during rain

storms, water may be present in the surrounding area of the pump. Caution

must be used to prevent bodily injury when working near the pump.

4. Do not run the pump in a dry basin. If the pump is run in a dry basin, the

surface temperature of the pump will rise to a high level. This high level

could cause skin burns if the pump is touched and will cause serious damage

to your pump.

5. Do not oil the motor. The pump housing is sealed. A high grade dielectric

oil devoid of water has been put into the motor housing at the factory. Use

of other oil could cause serious electric shock and/or permanent damage

to the pump.

6. Do not install in locations classified as hazardous in accordance with the

National Electrical Code, ANSI/NFPA 70.

7. When a pump is in a basin, etc., do not touch motor, pipes or water until

unit is unplugged or shut off. If your installation has water or moisture

present, do not touch wet area until all power has been turned off. If shut-off

box is not accessible, call the electric company to shut off service to the

house, or call your local fire department for instructions. Failure to follow

this warning can result in fatal electrical shock.

8. The flexible PVC jacketed cord assembly mounted to the pump must not be

modified in any way, with the exception of shortening the cord to fit into a

control panel. Any splice between the pump and the control panel must be

made within a junction box and mounted outside of the basin, and comply with

the National Electrical Code. Do not use the power cord for lifting the pump.

INSTALLATION

This pump must be used with a control panel which incorporates thermal

or overload protection and stalled-rotor conditions and shall be rated or

set to a maximum ampere rating as noted below.

Refer to the instructions supplied with the control panel for all safety and installa-

tion procedures. Care should be taken to prevent pump running in a dry sump.

18S-CIM

CONTROL

VOLTS

AMPS

AMP

SETTING

230

11.5

16

MAX

460

5.3

10

MAX

200-208

13.5

16

MAX

Improper impeller rotation will result in damage to the pump. Rotation

must be checked at installation.

After completing the wiring and with the

disconnect switch in the “OFF” position, lay pump on the side to observe

the direction of rotation through the intake.

NOTE:

contact with pump when

energized could result in electrical shock. Turn disconnect switch to the “ON”

position momentarily. The impeller should be rotating counterclockwise. An

alternate method is to observe the kickback of the freely suspended pump as

it starts. The kickback should be in counterclockwise direction looking onto the

top of the pump. To change the direction of rotation, interchange any two of the

white, red, or black wires of the pump at the disconnect box.

Pump must be installed in a suitable gas tight basin which is at least 24” in

diameter and 36” deep, and vented in accordance with local plumbing codes.

Pump must be placed on a hard level surface. Never place pump directly on

clay, earth or gravel surfaces.

Pump can be installed with ABS, PVC, polyethylene or galvanized steel pipe.

Proper adapters are required to connect plastic pipe to pump.

Always install a union in the discharge line, just above the sump pit, to allow for

easy removal of the pump for cleaning or repair.

A check valve must be used in the discharge line to prevent back flow of liquid into

the basin. The check valve should be a free flow valve that will easily pass solids.

CAUTION:

For best performance of check valves, when handling solids install in a

horizontal position or at an angle of no more than 45º. Do not install check valve in

a vertical position as solids may settle in valve and prevent opening on start-up.

1

SUBMERSIBLE

SEWAGE EJECTOR

PUMP (3-PHASE)

MODEL 18S-CIM

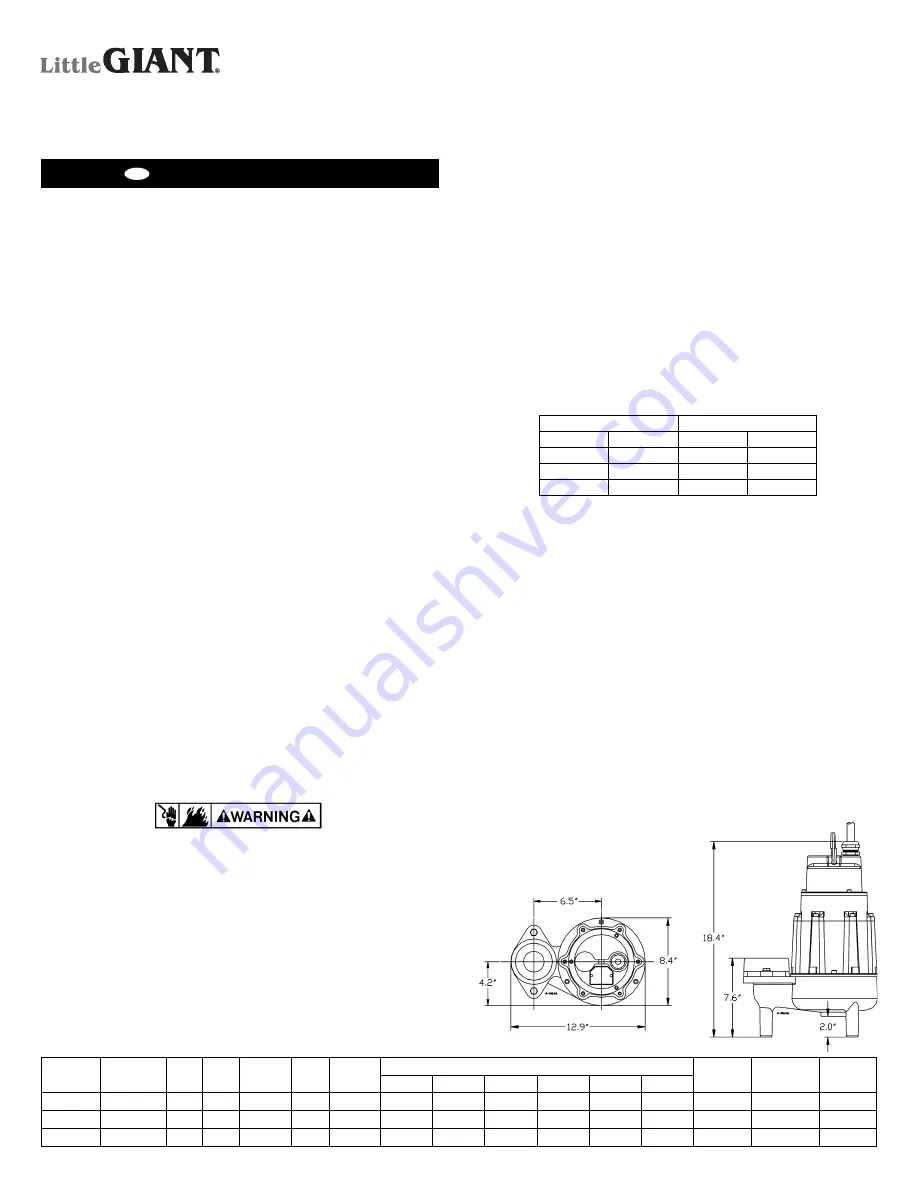

Figure 1

MODEL

NO.

CATALOG

NO.

HP

PH

VOLTS

HZ

AMPS

GPM @ HEAD

SHUT

OFF (Ft.)

POWER

CORD (ft.)

WEIGHT

(lbs.)

10’

20’

30’

40’

50’

60’

18S-CIM

520302

1.5

3

200-208

60

13.5

160

137

111

84

50

15

64

20

96

18S-CIM

520303

1.5

3

230

60

11.5

160

137

111

84

50

15

64

20

96

18S-CIM

520304

1.5

3

460

60

5.3

160

137

111

84

50

15

64

20

96

Franklin Electric Co., Inc.

P. O. Box 12010

Oklahoma City, OK 73157-2010

405.947.2511 • Fax: 405.947.8720

www.LittleGiantPump.com

Содержание 18S-CIM

Страница 5: ...5 Figure 4...