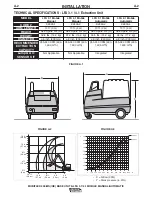

A-7

INSTALLATION

MOBIFLEX 400-MS(/HE) BASE UNIT & LFA 3.1/4.1 MOBILE MANUAL/AUTOMATIC

A-7

LFA 3.1/4.1 MOBILE AUTOMATIC

The K2633-2 or K2633-4 LFA 3.1/4.1 Mobile

Automatic extraction arm contains an integrated Lamp

& Arc Sensor Kit.

Installation Steps:

See Figure A.10 for steps 1-5

1. Mount the extraction arm LFA 3.1/4.1 Mobile

Automatic (A) on the post (B) using the two bolts

M8 and two selflocking nuts M8 with washers.

2. Remove the wire bridge from the supply cable

inside the base swivel mount.

3. Connect the supply cables of the Mobiflex 400-MS(/

HE) Base Unit and the extraction arm.

4. Remove the yellow tape from both arm sections.

5. Turn the extraction arm 359° and check whether

the supply cable is long enough. If necessary, pull

the supply cable of the Mobiflex 400-MS(/HE) Base

Unit to a sufficient length.

BALANCE CHECK

The extraction arms have been pre-balanced in the

factory for optimal balance and positioning. However,

they sometimes need adjustment. To check and adjust

the balance system, proceed as follows.

See Figure A.11

1. Bring the extraction hood to a horizontal position.

The hood should stay in this position.

If the extraction hood falls on its own:

(

See Figure A.12)

• Cut the tie wrap of the rubber protection cover which

is applied over the hood hinge.

• Pull down the protection cover.

• Turn bolt (A) in the hood hinge clockwise to tighten

extraction hood.

• Replace the protection cover and secure it with the

spare tie wrap supplied.

If the extraction hood does not stay to a horizon-

tal position (left/right):

(

See Figure A.12)

• Cut the tie wrap of the rubber protection cover which

is applied over the hood hinge.

• Pull down the protection cover.

• Turn bolt (B) in the hood hinge clockwise to tighten

horizontal movement.

• Replace the protection cover and secure it with the

spare tie wrap supplied.

FIGURE A.10

B

A

Do not remove the yellow tape

attaching both arm sections.

------------------------------------------------------------------------

ATTENTION

FIGURE A.11

FIGURE A.12

A

B