English 8 English

Controls and Operational Features

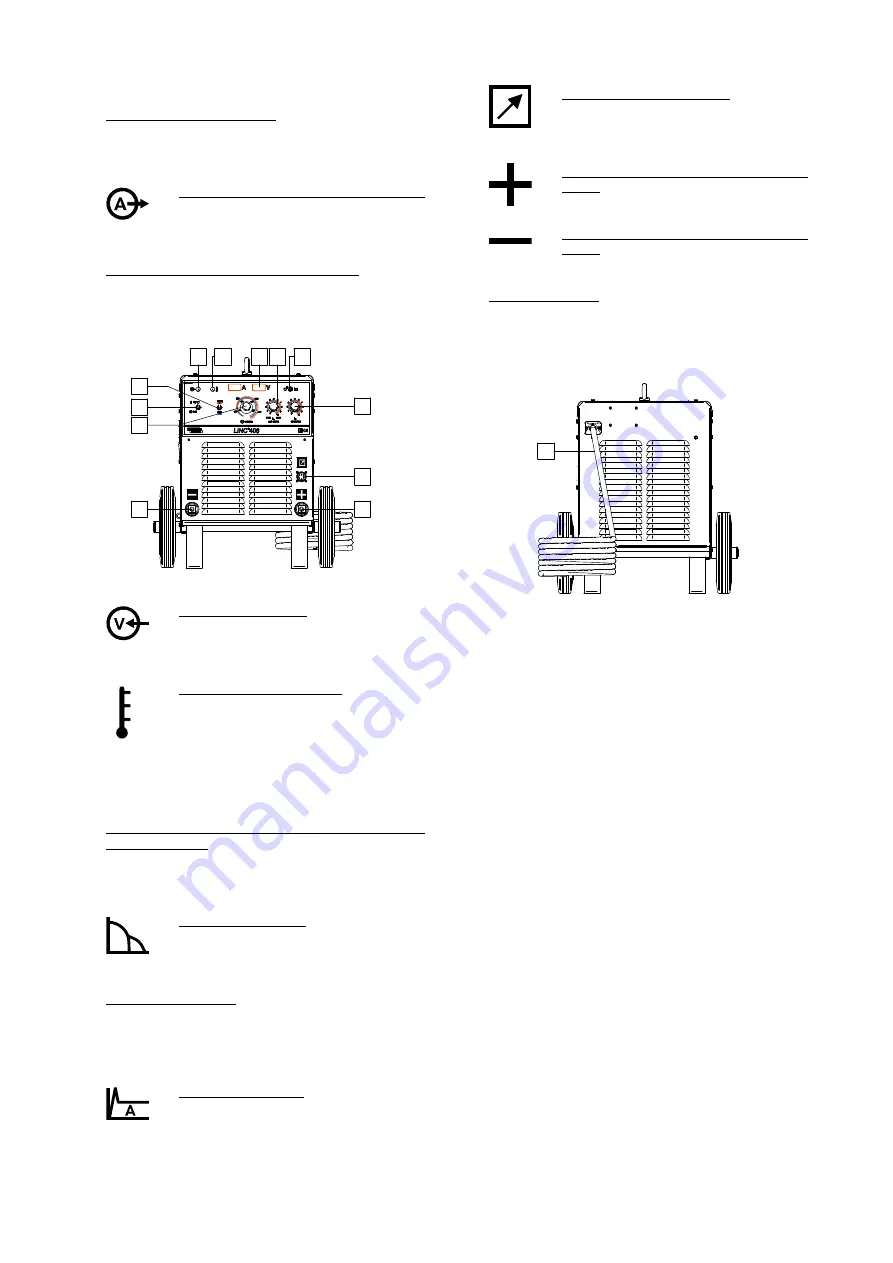

1. Power Switch ON/OFF (I/O): Controls the input power

to the machine. Be sure the power source is

connected to the mains supply before turning power

on (”I”).

2.

Welding Current Knob Control:

Potentiometer used to set the output

current on the range 30A - 400A (also

during welding).

3. Output Current Control Range Switch: It allows

selection of the desired welding current range:

LOW range (30A - 200A)

HIGH range (50A - 400A).

1

4

5

6 7

8

9

2

10

11

12

3

Figure 2.

4. Power Indicator Light: After input power is

connected and the power switch is turned

on, this lamp will light up to indicate the

machine is ready to weld.

5. Thermal Overload Indicator: This lamp will

light up when the machine is overheated

and the output has been turned off. This

can occur if the ambient temperature is

above 40°C or the duty cycle of the machine has been

exceeded. Leave the machine on to allow the internal

components to cool, when the lamp turns off normal

operation is possible.

6. Digital Welding Current and Voltage Meter with

memory feature: Shows the present value of the

welding current and voltage during welding; after

welding it continues to display the average welding

current and voltage for 5 seconds.

7. ARC FORCE Control: The output current

is temporarily increased to clear short

circuit connections between the electrode

and the workpiece.

8. Local/Remote Switch: Remote Control Unit K10095-

1-15M and K870 can be used with this machine. It

changes control of the Output Current from the

machine Welding Current [2] to the K10095-1-15M or

K870 and vice versa.

9. HOT START Control: Value in percentage

of nominal value welding current during

arc start current. The control is used to set

the level of the increased current and arc start current

is made easy.

10. Remote Control Connector: If a remote

control is used, it will be connected to the

remote connector (see "Accessories"

chapter).

11. Positive Output Socket for the welding

circuit: For connecting an electrode holder

with lead / work lead.

12. Negative Output Socket for the welding

circuit: For connecting an electrode holder

with lead / work lead.

13. Power lead (5m): Connect the supply plug to the

existing input cable that is rated for the machine as

indicated in this manual, and conforms to all applicable

standards. This connection shall be performed only by

a qualified person.

13

Figure 3.

Welding SMAW (MMA) process

LINC 406

does not include the electrode holder with lead

necessary and the work lead for SMAW welding, but the

one can be purchased separately (see "Accessories"

chapter).

For starting welding process with SMAW process you

should:

First turn the machine off.

Determine the electrode polarity for the electrode to be

used. Consult the electrode data for this information.

Connect output lead to output socket [11, 12] of the

machine and lock them.

Connect the work cable to the welding piece with the

work clamp.

Install the proper electrode in the electrode holder.

Connect the main plug to the outlet mains socket.

Turn the welding machine on.

Set the Local/Remote Switch in required position: local

or remote.

Set the required welding current by welding current

knob control [8].

Obeying appropriate rules you can begin to weld.