CALIBRATION

17

17

POWER WAVE CALIBRATION

ROBOTIC PW450 FULL VOLTAGE CALIBRATION

Service and repair should be performed by only Lincoln Electric factory trained personnel.

Unauthorized repairs performed on this equipment may result in danger to the technician or

machine operator and will invalidate your factory warranty. For your safety and to avoid elec-

trical shock, please observe all safety notes and precautions detailed throughout this manual.

If for any reason you do not understand the test procedures or are unable to perform the

test/repairs safely, contact the Lincoln Electric Service Department for electrical trou-

bleshooting assistance before you proceed. Call 1-800-833-9353 (WELD).

PROCEDURE DESCRIPTION

This procedure is necessary if the display board is replaced and the Quick Voltage Calibration

is NOT possible. The Full Voltage Calibration is also necessary if the snubber and/or control

boards are replaced.

MATERIALS NEEDED

A Test and Calibration Overlay L9660-255

A 300 amp ±10%, 30 volt resistive grid load. (A MIG welding load may be used if a grid

load is not available. Choose an argon rich 30 volt spray procedure.) See the topic

Full Voltage Calibration Using a Welding Arc in this section of the manual.

A calibrated DC voltmeter* accurate to 30.0 volts +/- 0.1 volt.

A set of jumper leads to access the remote voltage sensing leads in the wire feeder

amphenol receptacles.

* Some voltmeters will not read accurately because of the 40 KHz ripple present on the output.

SETUP PROCEDURE

1.

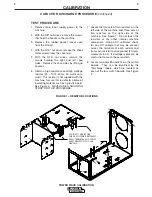

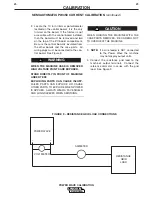

Using the jumper leads, connect wire #67, pin (N), located in wire drive receptacle P83,

to the machine’s positive output terminal.

2.

Using the jumper leads, connect wire #21A, pin (H), located in the auxiliary receptacle

P84, to the machine’s positive output terminal.

3.

Connect the resistive grid load (or wire feeder) to the machine’s output terminals.

4.

Connect the DC voltmeter to the machine’s output terminals. Do not connect the volt-

meter to the load. This avoids erroneous readings due to cable drop.

WARNING