11

4.3.2

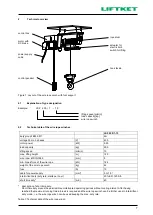

Adjustment of the electric limit switch

The load hook switches off the lifting motion by touching the actuator of the limit switch (see Figure 6). The switch

point is pre-set at the factory.

The limit switch should be activated immediately after the hook touches the actuator. The switch cam is adjustable

and attached to the shaft by a small threaded pin.

Figure 7: Winding scheme

4.3.3

Hazardous operations

If the operator doesn’t switch off the lowering motion after the load has reached the ground or the winch is assembled

higher than the length of rope allows, the rope could accidentally be fully released and rewound in the wrong direction.

The direction of motion will no longer comply with the symbols on the buttons.

Further operation of the wire rope winch is prohibited!

Another reason for a wrong direction of motion may be, that the wire rope is trapped between loose windings / layers

of the lower rope windings. In case of wrong motion direction, the load will be lifted despite of the button for lowering

is pressed. If the highe

st hook position is reached in this case, the limit switch won’t work anymore and this could

cause a rope or winch casing to break and the load to be dropped.

Further operation of the wire rope winch is prohibited!

If the failure in direction motion is recognized during the operation, the rope must be driven back to the start point of

wrong direction winding, the cause of malfunction has to be removed and the operation can be continued in the right

direction.

In case of wrong winding motion, if the hook tackle has touched the limit switch actuator, no further movement up or

down will be possible.

After disconnecting the power supply, the L1 and L2 wires must be interchanged to allow the hook to leave the limit

switch area. The original connection must then be re-established.

The problem which has led to the wrong lifting direction has to be sorted out as above.

The wire rope must be wound up regularly and tightly (Use safety gloves!).

Check, that the wire rope is undamaged.

Caution!

When lowering the hook, it is not permitted to release all rope from the drum. A minimum of four

windings should remain on the drum to avoid winding in the wrong direction.

rope drum

suspension plate

unwinded rope

limit switch

cam with

threaded pin