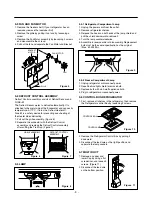

7-2-5 Function TEST

1. This is a compulsory operation for TEST, SVC, cleaning, etc. It is operated by pressing the water supply control KEY for 3 seconds.

2. It operates in the Ice Making mode, but not in the Ice-Removing mode or water supply process. (If there is an ERROR, it

can only be checked in the TEST mode.)

3. If the water supply control KEY is pressed for 3 seconds in the Ice-Making mode (no matter what condition the Ice-

Making tray is in) the Ice-Removing operation starts immediately. Water is not yet frozen, so water is poured instead of

ice. If the control doesn’t operate normally in the TEST mode, check and repair as needed.

4. After water is supplied, the normal CYCLE is followed:

ice making

→

Harvest

→

Fill

→

Park Position

.

5. When Stage 5 is completed in the TEST mode, minimize MICOM in 5 seconds, the time needed to supply water resets to

the previous status in the TEST mode.

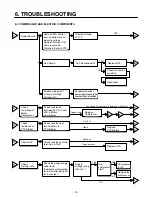

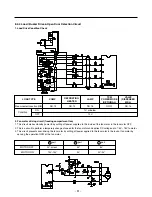

Diagnosis TABLE

7-3 DEFECT DIAGNOSIS FUNCTION

7-3-1 ERROR CODES shown on Ice Maker water supply control panel

ERROR indicators in table can be checked only in TEST mode.

-

23

-

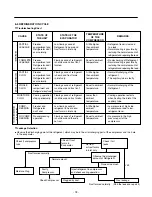

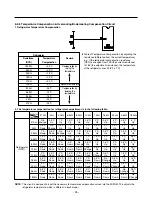

STAGE

ITEMS

INDICATOR

REMARKS

1

2

3

4

5

6

HEATER

MOTOR

HALL IC (detection

of position)

I

VALVE

HALL IC (detection

of full-filled Ice)

II

reset

Five seconds after heater starts, heater will

go off if temperature recorded by sensor is

10°C or lever is in up position.

Five seconds after heater starts, you can

confirm that motor is moving.

You can confirm Hall Ic detection of position.

Two seconds after detection of initial

position, you can confirm that valve is on.

You can check whether hall is sensing Full

ice condition. (If there is a full-filled error, the

fifth LED is not on.)

Five seconds after fifth stage is completed,

the icemaker reset at initial status.

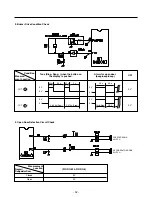

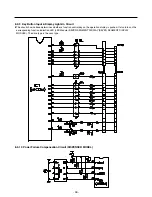

NO

DIVISION

INDICATOR

CONTENTS

REMARKS

1

2

3

Normal

Ice-Making

Sensor

malfunction

Ice Maker Kit

malfunction

Mark time to

supply

Mark previous status on TEST mode

None

Cut or short-circuited wire

When ejector blades don’t reach

park position over 18 minutes

since Harvest Mode starts.

Display switch

operates properly

Make sure that the wire

on each sensor is

connected.

Defects of

HALL IC/MOTOR/

HEATER/RELAY

Содержание LRBC22522

Страница 12: ...GY GRIS GRAY Best Best dispenser 5 CIRCUIT DIAGRAM 12 ...

Страница 13: ...GY GRIS GRAY Good Better 13 ...

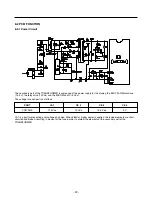

Страница 40: ...8 5 MAIN PWB ASSEMBLY AND PARTS LIST 8 5 1 Main PWB Assembly 40 ...

Страница 41: ...8 5 2 Replacement Parts List 41 ...

Страница 42: ...8 5 3 PWB Assembly Display And Parts List 42 SW106 Dispenser Model Best Model ...

Страница 44: ... 44 FREEZER SENSOR FREEZER DOOR SWITCH REFRIGERATOR DOOR SWITCH REFRIGERATOR SENSOR DEFROST SENSOR 220 1 2W ...

Страница 60: ...9 5 MAIN PWB ASSEMBLY AND PARTS LIST 9 5 1 Main PWB Assembly 60 ...

Страница 61: ...9 5 2 Replacement Parts List 61 ...

Страница 62: ...9 5 3 PWB Assembly Display And Parts List 62 ...

Страница 63: ...9 6 PWB DIAGRAM 9 6 1 PWB Main Assembly 63 G5S 1A RY5 ...

Страница 64: ... 64 ...

Страница 70: ...June 2009 ...