LGETH -180704-054

/ Rev. 0

LG Electronics

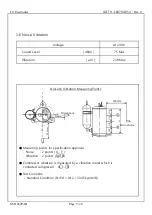

Frequency Range

Rated Frequency

±

2%

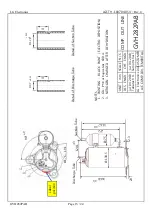

Pipe Stress

Don’t allow any force on discharge & suction pipe .

The piping stress must be less than 300

㎏

f/

㎠

at starting and stopping.

And less than 153

㎏

f/

㎠

at running.

Oil Level

It must be checked oil level by the compressor with

sight glass we supply. And oil level must be kept over

guide line level **

note 3.

at any condition.

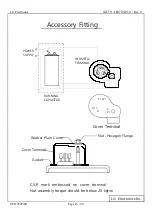

Protection device

Refrigeration system must has the compressor protection device like

over pressure, high temperature, sensing locked pump in the controller.

When starting & running fail by abnormal overload, controller must be

able to cut off power of compressor before motor burn out.

An earth terminal should be installed to prevent electrical accidents.

3.2 Application Limit

Page 10 / 24

GVH282PAB

Pump down

refrigerant

If pump down time is too long, compressor can be damaged due to

excessive temperature increase or poor lubrication.

Guideline of pump down process.

- Time : less than 30 seconds

- Suction Pressure : It should not run under below 1

㎏

f/

㎠

G.

And before closing a service valve, compressor running for more than 5

minutes is recommended.

※

If gas charge amount of refrigerant specified is exceeded,

both parties should discuss the matter to determine compressor specification.

(accumulator volume, lubricating oil amount) and system specifications (crank case

heater, oil separator , additional accumulator, etc)

This document will be effective after LG’s receipt with your authorized signature.

When design modification is approved by the customer , the current document is

unavailable.

* Effective Period of This Document *