LH-20S USER MANUAL

10

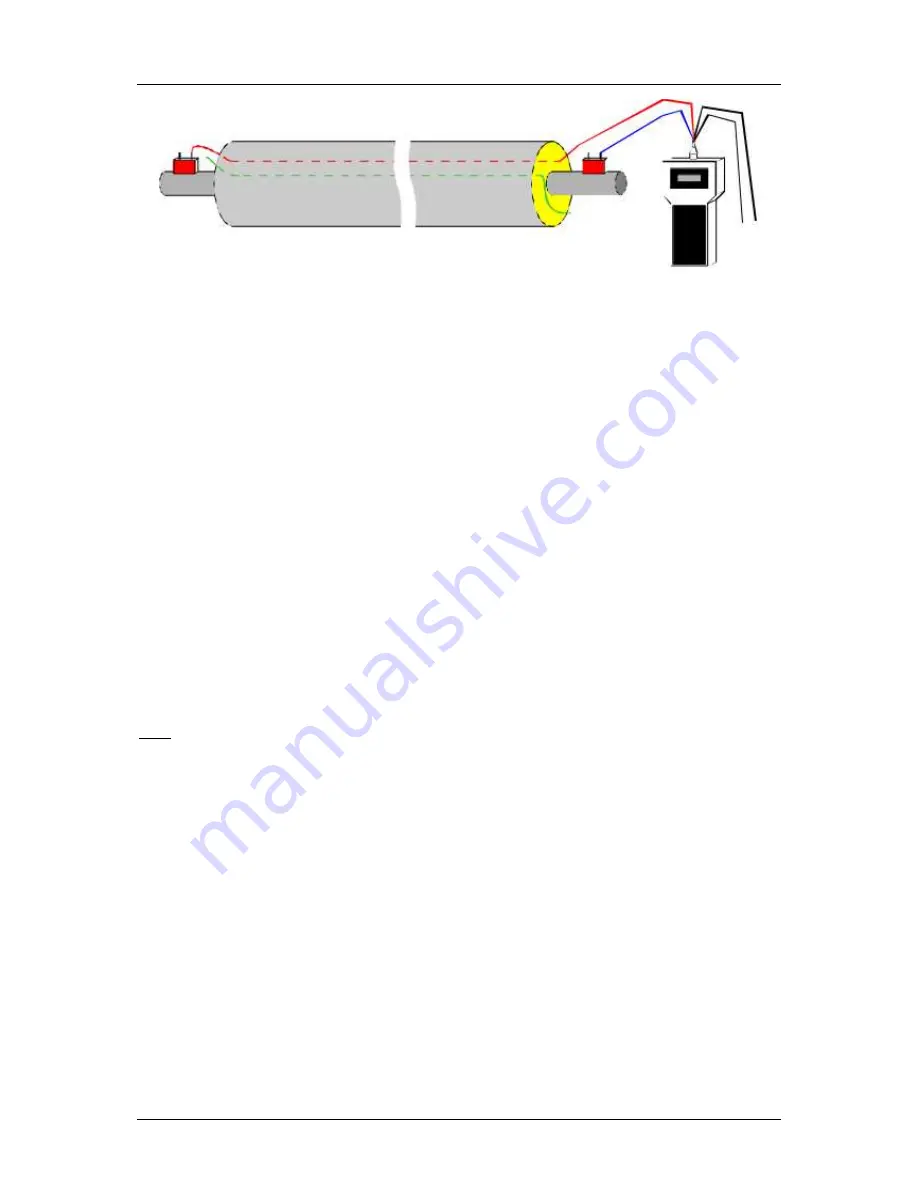

Fig. 7. Testing the resistance wire for mechanical damage

In order to test the resistance wire, first connect the resistance wire to the carrier pipe at one

end of the alarm loop (e.g. in the connecting box or as shown in fig. 7). Then, connect the red

and blue detector wires respectively with the second end of the tested wire and with the

magnetic connector attached to the carrier pipe. Measurement results depend on the length of

the tested wire (5.7

Ω

/m) and on the resistance of the contact between the magnetic connectors

and the carrier pipe. If the connections are made correctly, then the detector simply displays

the length and resistance of the tested wire. If the Przerwana p

ę

tla (Open Loop) or HI

message appears or if measurement results are highly unstable, then the resistance wire of the

alarm loop is faulty. The displayed message and measurement results help to determine the

type of fault. (See example results and comments.) If a break in the alarm loop is detected,

then further actions depend on the structure of the heating pipeline system. If the pipeline has

no branches, locate the fault with the reflectometer. If the pipeline has branches, first isolate

the faulty section of the wire by disconnecting the connections of the alarm loop in all

terminal boxes. Then, the condition of each section should be tested almost in accordance

with the above-described method and fig. 7. The only difference is that, in the branches, the

resistance wire may be extended with the copper wire. In such case, connect the end of the

wire to the pipe.

In general, breaks in the isolated sections of the alarm loop wire should be located with a

reflectometer. Capacitive measurement method may be used to locate the break in the wire

only if there is no moisture in the area of the wire break (result 1).

Note: In each of the above-described secondary measurements, any information displayed in

the first line of the detector display is insignificant. The first line of the display may display

the MH=0; >99M

Ω

result if the black detector wires are connected together or the Brak

kontaktu (No Contact) message if the detector wires are not connected together.

When one of the wires of the alarm loop is connected to the carrier pipe, a substitute loop is

formed. In such cases, the pipe serves as a reference point, because there are no breaks in it

and because its resistance is almost equal to 0

Ω

. In making such substitute loops, it is crucial

to achieve minimal resistance values of the contact with magnetic connectors (figs. 5;7).

Sometimes, the difficulty in making connections is the distance between the end of the tested

wire and the access point to the carrier pipe to which the connector is to be connected. It is

easier to make the connections if you make substitute loops from wires located in two parallel

sections of the heating pipeline system. First, however, ensure that the wires used as

substitutes are not faulty. Connections between separate sections of the alarm loop should be

made with the use of terminal boxes. For non-faulty sections, length measurement values are

twice as high as specified in the technical documentation.

D

E

T

E

C

T

O

R