User Manual for BPS-200

www.levitronix.com

PL-4012-00, Rev07, DCO# 20-144

34

9

Appendix

9.1 Regulatory Status

9.1.1 CE Marking

The

Centrifugal Pump System Family BPS-200

, in its configurations as listed below is in conformity with the below

mentioned

European Directives

. The various configurations of the pump system are thought to be used in hydraulic

circuits of industrial production equipment of the Semiconductor, Chemical, Life Science (Biotech, Pharmaceuticals) and

other machinery markets.

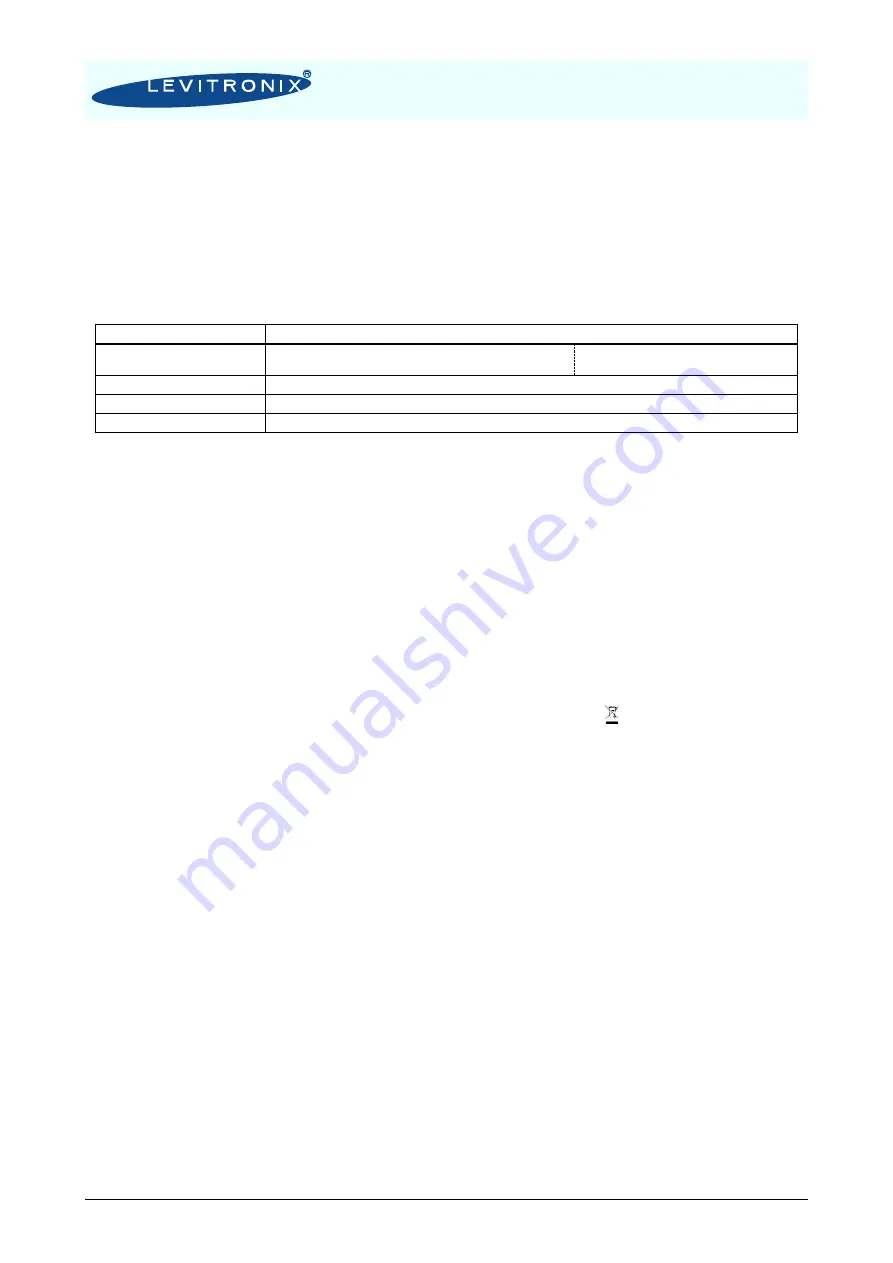

Part Name

Description

LPP-200.x

Pump casing configurations consisting of variations

concerning fittings, O-Rings, wet materials and performance

and impellers with various materials and

performance variations

BSM-1.x

Bearingless motors:

BSM-1.x

(x = various cable, connector and coating options)

LPC-200.x

Controllers with 24

– 48V DC inputs:

LPC-200.x

(x = various interfacing options)

Accessories

Motor controller adaptor cables of various length, air cooling module and others

Machinery Directive 2006/42/EC:

The machinery directive essentially has been followed by a risk analysis, according mitigation actions and a user manual

for safe operation. For the design and testing the following standards are used as a guideline:

EN809

Pumps for Fluids: basic requirements are followed.

EN12162

Procedure for hydrostatic pressure testing in fluid pumps: used for max. pressure testing of pump head.

ISO12100

Safety for machinery

– principles for risk assessments: used for system risk analysis.

EMC Directive 2014/30/EC:

The following standards of the EMC directive are tested and confirmed at a certified laboratory:

EN61000-6-2

Generic standards, Immunity for industrial environments

EN61000-6-4

Generic standards, Emission standard for industrial environments

9.1.2 Disposal of Equipment

– WEEE Directive 2012/19/EU

Follow local legislation for disposal of equipment. In the European Union (EU) marked (

) devices are governed by the

European WEEE Directive 2012/19/EU. Do not dispose with normal waste.

9.1.3 IECEE CB Safety Certification

Specific motors with pump heads and controllers of the

Centrifugal Pump System BPS-200

are 3

rd

party

tested and certified by

Electrosuisse

following the

IECEE CB Scheme

according to the following safety

standards:

IEC61010-1

Safety requirements for electrical equipment for measurement, control and laboratory use.

The CB certification number is

CH-7695

.

9.1.4 NRTL/ETL Safety Certification and Marking

Specific motors with pump heads and controllers of the

Centrifugal Pump System BPS-200

are tested by

the US national recognized laboratory (NRTL)

Intertek

according to the following safety standards:

UL61010-1

Safety requirements for electrical equipment for measurement, control and laboratory (US Standard).

CSA-C22.2

No. 61010-1-12

Safety requirements for electrical equipment for measurement, control and laboratory use (Canadian Standard).

UL1004-1

Rotating Electrical Machines - General Requirements (US standard).

The ETL control number for the listing is

4010272

.