User Manual for BPS-4H (High Temp.)

www.levitronix.com

PL-2009-03, Rev04, DCO# 21-101

6

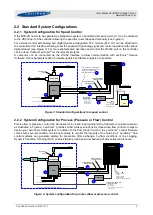

2.2 Standard System Configurations

2.2.1 System Configuration for Speed Control

If the

BPS-4H

needs to be operated as standalone system a handheld user panel (

LUI-A.1

) can be attached

to the

RS232

port of the controller allowing the operator to set the speed manually (see

).

For external control with analog and digital signals a designated

PLC

module (

PLC-A.1

) can be attached to

the controllers

PLC

interface allowing to set the speed with an analog signal and control operation with various

). For more sophisticated operation and control the

RS232

port on the controller

can be used. Contact

Levitronix

®

for the relevant protocol.

A computer can be connected via the

RS232

interface to allow communication with

Levitronix

®

Service

Software

. Hence parameterization, firmware updates and failure analysis are possible.

Figure 3: Standard configurations for speed control

2.2.2 System Configuration for Process (Pressure or Flow) Control

Precise flow or pressure control can be realized in a closed loop together with a flowmeter or pressure sensor

as illustrated in

Levitronix

provides either turnkey solutions for closed-loop flow control or helps to

design your own flow control system. In addition to the flow control function, the

Levitronix

control firmware

comes with several condition monitoring features to monitor the integrity of the fluid circuit.

Levitronix

flow

control systems can generate alarms for preventive filter exchange, no-flow conditions or line clogging.

Dynamic Condition Trending (DCT) enables failure prediction and scheduling of preventive maintenance.

Figure 4: System configuration for process (flow or pressure) control

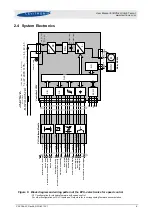

Controller

Chemical Resistance and IP67 Space

Pump Head

Motor

Fluid In

Cooling Fluid Out

Motor Sensor Cable

Motor Power Cable

RS232

- Intelligent Control

- Service

- Firmware Update

- Configuration etc.

Adaptor/Extension

Cable for Sensors

Adaptor/Extension

Cable for Power

PLC Interface:

Speed Setting

- 3 Digital Inputs

- 3 Digital Outputs

- 2 Analog Inputs

- 2 Analog Outputs

AC 200-240 V

PLC Module

Fluid Out

Cooling Fluid In

Suction Port

(closed)

LUI

User Panel

either

or

Controller

Chemical Resistance and IP67 Space

Pump Head

Motor

Fluid In

Cooling Fluid Out

Motor Sensor Cable

Motor Power Cable

RS232

- Intelligent Control

- Service

- Firmware Update

- Configuration etc.

- Standalone Operation with LUI

Flow- or

Pressure

Sensor

Adaptor/Extension

Cable for Sensors

Adaptor/Extension

Cable for Power

PLC Interface: Speed, Flow

or Pressure Setting

- 3 Digital Inputs

- 3 Digital Outputs

- 2 Analog Inputs (1 occupied by sensor)

- 2 Analog Outputs

AC 200-240 V

PLC Module

Fluid Out

Cooling Fluid In

Suction Port

(closed)

2

1

3

8

9

5a

5b

If connectors are placed within

the chemical area the protection

set LCP-S.1 can be used

(see

Pos. 9)

9

2

1

3

8

5a

5b