Mechanical installation

Mounting of g500 short/servo adapters with clamping connection

Maximum permissible load at the motor adapter

26

Lenze ¯ MA 12.0018 ¯ 4.1

Drive size

Distance L

Tab

of

the motor

Gearbox type

IEC

NEMA

g500−S8000

G50BS280

g500−S14000

G50BS314

g500−S19000

G50BS319

[mm]

Maximum permissible force F

M Tab

[N]

T

H

51

A

B

14

115

−−−−−

−−−−−

−−−−−

55

18

145

2210

−−−−−

−−−−−

55

−

145

2490

2450

2450

61

21

190

4480

4420

4420

65

25

250

5230

5230

5230

66

28

250

4500

4500

4500

70

−

300

3720

3720

3720

76

32

300

7100

7100

7100

81

36

400

6880

6880

6880

82

−

400

11400

11400

11400

4.3.6

Mounting of g500 short/servo adapters with clamping connection

Important notes

¯

The transmission is made in a force−fitting manner via a clamping connection.

Greases, oils and other substances which reduce the friction factor reduce the

torque to be transmitted which is why these should be avoided in the connection.

¯

The motor shaft diameter must be designed with fit k6.

¯

The motor centering diameter must be designed with fit j6.

¯

With regard to smooth running tolerance of the motor shaft, concentricity of the

centering and axial runout of the mounting flange, the motor must fulfil the

requirements according to DIN 42955 R (reference values for smooth running <

0.025 mm; axial runout and concentricity < 0.05 mm).

4

5

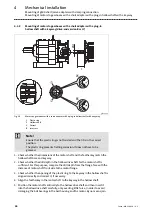

Fig. 3

Measurement of the surfaces of smooth running, axial runout and concentricity

4

Motor flange

5

Centering