Determination of the required gearbox load capacity

Define the required load factor at runtime t

L

Runtime t

L

≤ 10 %

Take the load factor k from diagram into account

Runtime t

L

> 10 %

Take intensity k

I

from calculation into account

Calculate intensity

no alternating load

k

I

= M

L,max

/ M

L

k

I

=

at alternating load

k

I

= M

L,max

/ M

L

x 1.4

k

I

=

Load factor k

0

1

2

3

4

5

6

7

8

9

10 %

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

1.3

1.2

1.5

1.7

1.9

2.1

2.3

2.5

2.7

2.9

3.1

3.3

3.5

3.7

3.9

4.1

4.3

4.5

4.7

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

3.2

3.4

3.6

3.8

4.0

4.2

4.4

4.6

24 h 16 h

8 h

k = 5

I

k = 4

I

k = 3

I

k = 2

I

I

II

III

IV

t

L

k

Operating mode S1

Calculation of the required drive power

Calculation

Result

Unit

Output torque

M

R

≥ M

L

/ (k

L

x k

H

)

M

R

=

Nm

Output speed

n

R

≥ n

L

/ k

E

n

R

=

rpm

Drive power

P

R

≥ M

R

x n

R

/ 9549

p

R

=

kW

Check geared servo motor and determine from the selection table

Check

Selection

Unit

Drive power

P

1

≥ P

R

p

1

=

kW

Output torque

M

2

≥ M

L

M

2

=

Nm

Output speed

n

2,th

≥ n

L

n

2,th

=

rpm

Load capacity of the geared motor

c ≥ k

c ≥ k

I

c =

Short-time maximum torque

no alternating load

M

2,max

≥ M

L,max

M

2,max

=

Nm

at alternating load

M

2,max

x 1.5 ≥ M

L,max

M

2,max

=

Nm

Ratio

i =

Information on project planning

Drive dimensioning

26

Содержание g500-H100

Страница 1: ...Geared servo motors g500 H m850 helical geared servo motor Project planning EN...

Страница 2: ......

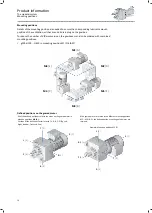

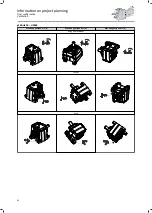

Страница 15: ...Position of the ICN connectors R L B T Product information The modular system Mounting positions 15...

Страница 155: ......

Страница 156: ...06 2021 2 0 www Lenze com...