Page 31

6. Primary Limit Control (S10)

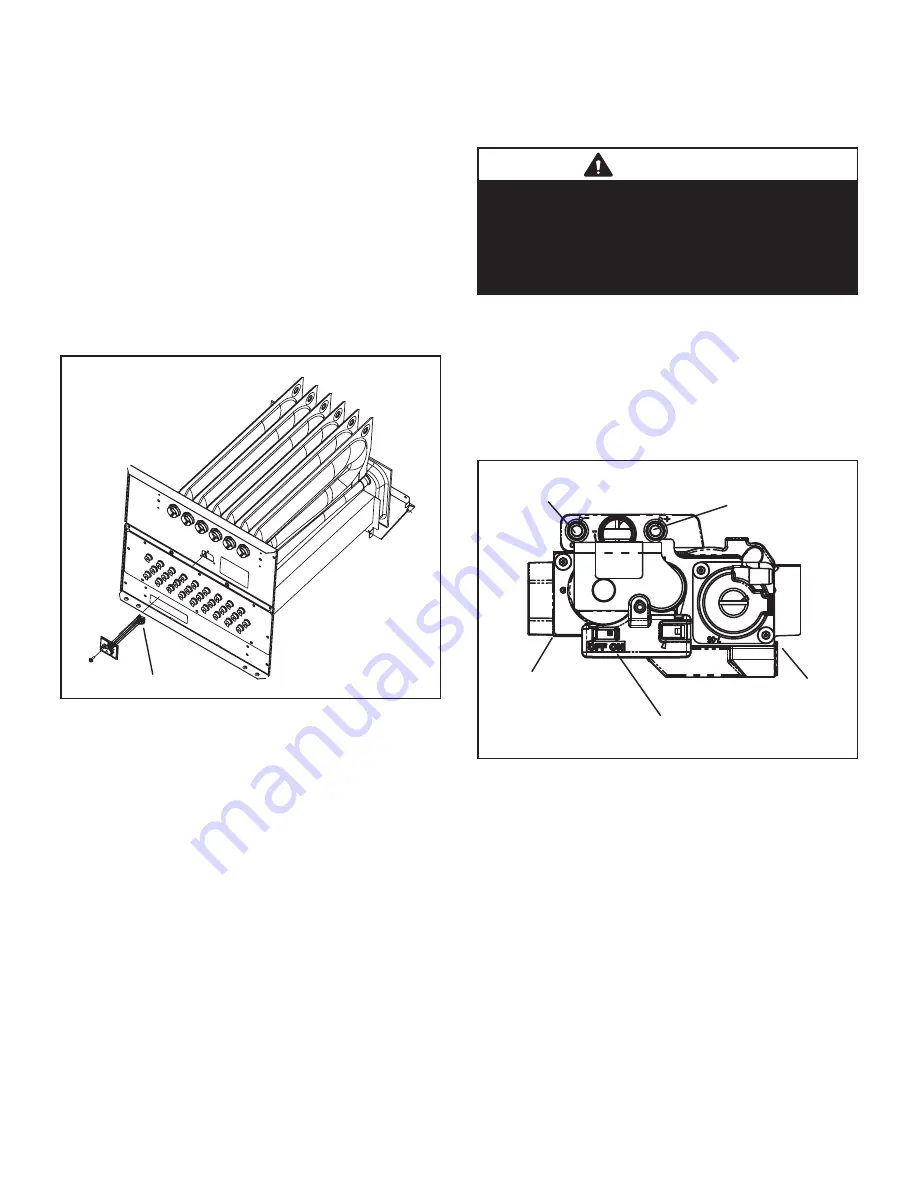

FIGURE 15 shows the primary limit (S10) used on

SLP99DFV units located in the heating vestibule panel.

When excess heat is sensed in the heat exchanger, the

limit will open. Once the limit opens, the furnace control

energizes the supply air blower and de-energizes the

gas valve. The limit automatically resets when unit tem-

perature returns to normal. The switch is factory set and

cannot be adjusted. In the event of restricted air flow, the

integrated control will reduce firing rate and indoor blower

airflow in 10% increments until a sustainable air flow is

reached. If the furnace reaches 35% firing rate, and ade

-

quate air flow is not available, the furnace will shutdown

and enter one hour watchguard. For limit replacement re-

move wires from limit terminals and rotate limit switch 90

degrees. Slowly remove from the vestibule panel.

Primary Limit Location and Heat Exchanger

install limit face down

FIGURE 15

7. Gas Valve (GV1)

Units use a variable capacity gas valve (figure 16) and

is applicable for two-stage or variable capacity settings.

See “Thermostat selection modes” in the integrated con-

trol section (section A- subsection 4.) for more details The

valve is internally redundant to assure safety shut-off. If

the gas valve must be replaced, the same type valve must

be used.

A 24VAC 2-pin plug and gas control switch are located on

the valve. 24V applied to the pins enables valve operation.

Inlet and outlet pressure taps are located on the valve.

LPG change over kits are available from Lennox. Kits in-

clude burner orifices and an LP gas valve.

DANGER

Danger of explosion.

There are circumstances in which odorant used

with LP/propane gas can lose its scent. In case of

a leak, LP/propane gas will settle close to the floor

and may be difficult to smell. An LP/propane leak

detector should be installed in all LP applications.

The burner box is sealed and operates under a negative

pressure. A pressure hose is connected from the burner

box to the gas valve. The gas valve senses the pressure in

the burner box and uses that to set the maximum manifold

pressure while the pressure switch with pressure condi-

tioning device adjusts the gas flow. This will compensate

for different vent configurations which can greatly affect

the rate of the unit.

GAS VALVE

NEGATIVE AIR

PRESSURE PORT

POSITIVE AIR

PRESSURE PORT

MANIFOLD

PRESSURE TAP

INLET

OUTLET

SUPPLY

PRESSURE

TAP

GAS VALVE SHOWN IN THE ON POSITION

FIGURE 16