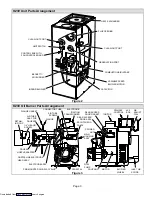

Page 12

Oil Supply Line & Filter Connections

One−Pipe Systems

CAUTION

Do not install the bypass plug into the pump on one−

pipe systems.

The burner is shipped with fuel pump set for one−pipe op-

eration. For one−pipe systems, the oil supply pipe is con-

nected to the inlet tap on the pump. A one−pipe system

should only be used where there is gravity oil flow to the

pump and the pipe is not run at any point above the oil level

in the tank.

1. Connect the inlet pipe to the pump inlet. Start the burn-

er.

2. Set the primary burner control for continuous opera-

tion during purging.

3. Turn the bleed valve one turn counterclockwise to

open.

4. Bleed the unit until all air bubbles disappear.

NOTE − Hurried bleeding will prevent the unit from op-

erating properly.

5. Tighten the bleed valve securely.

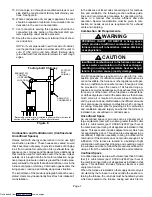

Two−Pipe Systems

If the installation requires a two−pipe operation, install the

bypass plug included in the bag which is attached to the

pump. To convert the pump, install the bypass plug ac-

cording to the provided pump instructions. Notice in the

two-pipe system the return pipe must terminate in the tank

3" (76 mm) to 4" (102 mm) above the supply inlet. Ensure

the return pipe terminates at the correct measurement or

air may escape into the system. This could result in loss of

prime.

NOTE− If using an outside tank in cold climates a number

one fuel or an oil treatment is strongly recommended.

1. Remove 1/4" plug from return port.

2. Insert bypass plug and tighten it (see figure 16).

3. Attach the return and inlet pipes. Start the burner. Air

bleeding is automatic.

NOTE − If a faster bleed is necessary, open the bleed

valve.

4. The return pipe must terminate 3" to 4" above the sup-

ply pipe inlet (see figure 16).

NOTE − If the return pipe does not terminate where it

should, air may enter the system, and prime may be

lost.

An oil filter is required for all models.

Install filter inside

the building between the tank shut-off valve and the burn-

er. Locate filter close to burner for easy maintenance.

Table 5 lists the filters for the O23V furnace.

Table 5

Installation Clearances inches (mm)

Oil Filters

Cat. No.

10 micron filter (no mounting bracket)

81P89

10 micron replacement cartridge for filter, 45 gph

53P93

Filter restriction indicator gauge

53P90

Consult burner manufacturer’s instructions packaged with

unit for further details concerning oil supply pipe connec-

tions.

Leak Check

After oil piping is completed, carefully check all piping con-

nections (factory and field) for oil leaks.

Oil Pipe Heater (Optional)

A heater for the oil pipe is available for applications that are

located in cold climates. The heater warms the oil pipe to

assist the initial start−up.

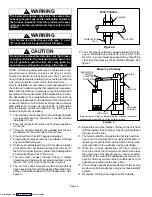

Electrical

Wiring must conform to current National Electric Code

ANSI/NFPA No. 70, or Canadian Electric Code Part I, CSA

Standard C22.1, and local building codes. Refer to figure

18 for wiring diagram and to unit nameplate for minimum

circuit ampacity and maximum overcurrent protection

size. Select the proper supply circuit conductors in accor-

dance with tables 310−16 and 310−17 in the National Elec-

tric Code, ANSI/NFPA No. 70 or tables 1 through 4 in the

Canadian Electric Code, Part I, CSA Standard C22.1.

CAUTION

USE COPPER CONDUCTORS ONLY.

This unit is provided with holes for conduit. Reducer wash-

ers are provided for sizing the hole to allow for smaller con-

duit. Use provided caps to seal holes not used. Refer to fig-

ure 17 for the terminal designations on the A54 blower

control board. Refer to figure 18 for unit schematic wiring

diagram with typical field wiring.

Separate openings are provided for 24V low voltage and

for line voltage. Refer to figure 1 for specific location.

WARNING

Run 24V Class II wiring only through specified low

voltage opening. Run line voltage wiring only

through specified high voltage opening. Do not

combine voltage in one opening.

1. Refer to the appliance rating plate for proper fuse size.

Downloaded from