Page 13

IMPORTANT

If using a programmable thermostat, be sure to use

a type of thermostat that retains its memory in event

of a power loss.

2. Install the room thermostat and make wire connec-

tions to the fan control board. Avoid installing thermo-

stat on an outside wall or where it can be affected by

radiant heat. Set the adjustable heat anticipator on

thermostat according to the wiring diagram sticker pro-

vided on unit.

3. Install a separate fused disconnect switch near unit so

power can be shut off for servicing.

4. Complete line voltage wiring from disconnect switch

near unit to make-up box.

NOTE − An equipment ground screw is provided. Re-

fer to unit wiring diagram and figure 18 for O23V series

units. Ground unit using a suitable ground wire.

5. Any accessory rated up to 1 amp can be connected to

the EAC terminal. (EAC terminal is energized when

the blower is operating.)

Blower Control

WARNING

Electric shock hazard. Can cause

injury or death. Before attempting to

perform any service or maintenance,

turn the electrical power to unit OFF at

disconnect switch(es). Unit may have

multiple power supplies.

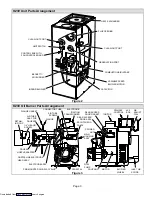

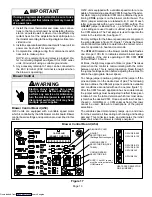

Blower Control Board (A54)

O23V units are equipped with a variable speed motor

which is controlled by the A54 blower control board. Blower

control board settings and operation are described in this

section.

O23V units equipped with a variable speed motor are ca-

pable of maintaining a specified CFM throughout the exter-

nal static range. A particular CFM can be obtained by posi-

tioning

COOL

jumpers on the blower control board. The

COOL jumper selections are labeled A, B, C and D; each

letter corresponds with an air volume (CFM) setting. The

ADJUST

jumper is labeled Test, −, +, and Norm. The + and

− pin settings are used to add or subtract a percentage of

the CFM selected. The Test jumper is used to operate the

motor in the test mode. See figure 17.

Factory settings for the blower speed jumpers are given in

the wiring diagram in figure 18. Figure 17 shows the blower

control board. Use table 6 to determine the correct air vol-

ume for operation in heat and cool mode.

The

CFM

LED located on the blower control board flashes

one time per 100 cfm to indicate selected blower speed.

For example, if the unit is operating at 1000 CFM,

CFM

LED will flash 10 times.

At times, the light may appear to flicker or glow. This takes

place when the control is communicating with the motor

between cycles. This is normal operation. Read through

the jumper settings section before adjusting the jumper to

obtain the appropriate blower speed.

To change jumper positions, gently pull the jumper off the

pins and place it on the desired set of pins. The following

section outlines the different jumper selections available

and conditions associated with each one (see figure 17).

After the CFM for each application has been determined,

the jumper settings must be adjusted to reflect those given

in table 6. From the table, determine which row most close-

ly matches the desired CFM. Once a specific row has been

chosen (+, NORMal, or −), CFM volumes from other rows

cannot be used. Below are descriptions of the jumper

selections.

The variable speed motor slowly ramps up to and down

from the selected air flow during both cooling and heating

demand. This minimizes noise and eliminates the initial

blast of air when the blower is initially energized.

Blower Control Board (A54)

16−PIN PLUG

(BOARD TO MOTOR)

DIAGNOSTIC LED

ADJUST

SELECTOR PINS

(Setting affect cooling only)

HEATING SPEED

SELECTOR PINS (SEE

TABLE)

COOLING SPEED

SELECTOR PINS

NOTE − The JW1 resistor

must be cut to activate the

HUM terminal.

Figure 17

O23V−Q2/3−090

O23V−Q3/4−120

O23V−Q2/3−070

O23V−Q3/4−105

O23V−Q5−140

O23V−Q5−154

HEAT SPEED SELECTOR

PINS (JUMPERS)

Downloaded from