Page 20

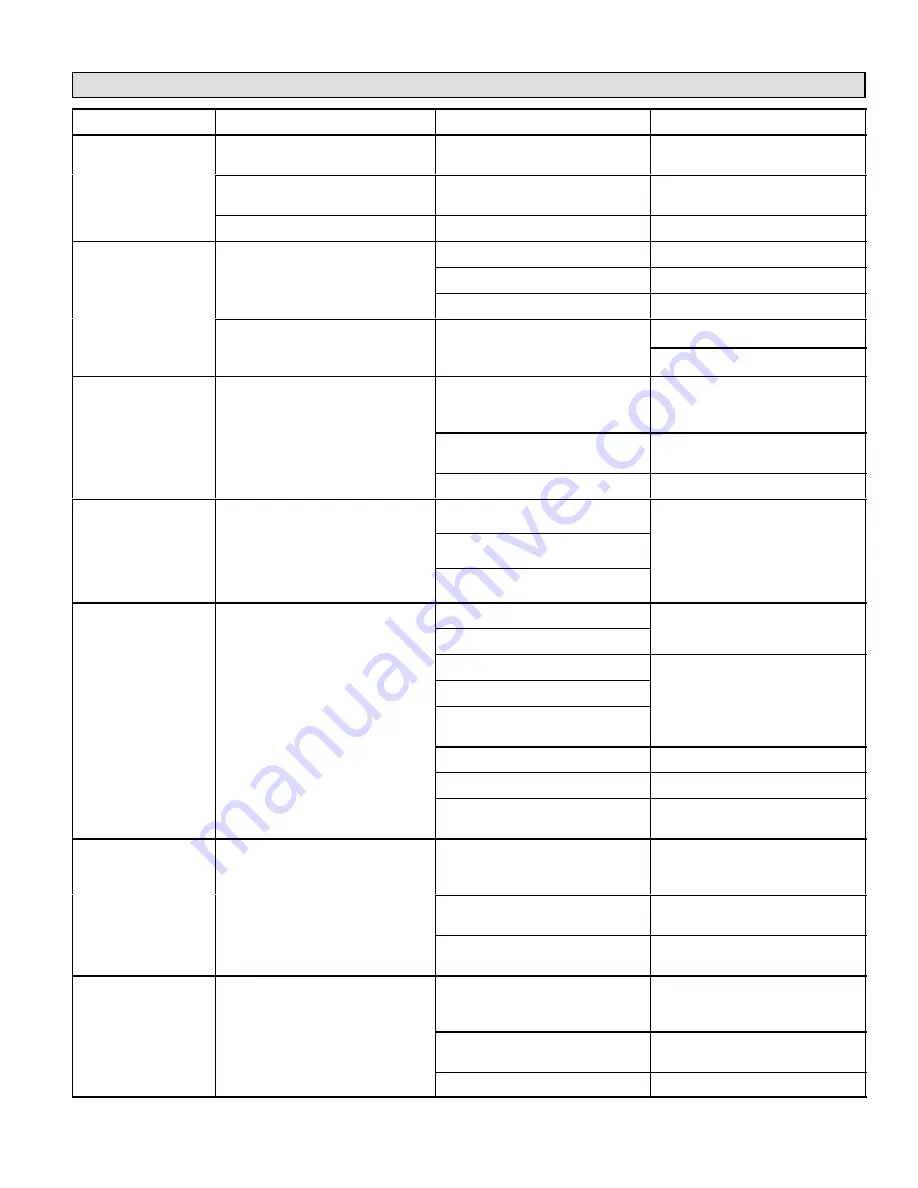

Troubleshooting: Burner starts, but no flame is established.

Source

Procedure

Causes

Correction

Check tank gauge or use dip

stick.

No oil in tank

Fill tank.

Oil Supply

Coat dip stick with litmus paste

and insert into bottom of tank.

Water in oil tank

If water depth exceeds 1 inch,

pump or drain water.

Listen for pump whine.

Tank shut−off valve closed

Open valve.

Oil line filter is plugged

Replace filter cartridges.

Listen for pump whine.

Kinks or restriction in oil line

Repair or replace oil line.

Oil Filters & Oil Line

Plugged fuel pump strainer

Clean strainer or replace pump.

Open bleed valve or gauge port.

Start the burner No oil or milky

Air leak in oil supply line

Locate and correct leak.

Start the burner. No oil or milky

oil indicates loss or prime.

Air leak in oil supply line

Tighten all connections.

Oil P

Install pressure gauge on pump

d

d

Sh

ld

t

Pump is partially or completely

frozen. No pressure and the

motor locks out on overload.

Replace pump.

Oil Pump

p

g

g

p

p

and read pressure. Should not

be less than 140 psi.

Coupling disengaged or broken

− no pressure

Re−engage or replace coupling.

Fuel pressure too low

Adjust to 100 psi.

Disconnect ignition leads. Ob-

serve the oil spray (gun assem-

Nozzle orifice plugged

Replace nozzle with the same

Nozzle

serve the oil spray (gun assem

bly must be removed from unit).

Inspect the nozzle for plugged

Nozzle strainer plugged

Replace nozzle with the same

size, spray angle, and spray

type

Inspect the nozzle for plugged

orifice or carbon build−up around

orifice.

Poor or off center spray

type.

Fouled or shorted electrodes

Clean electrode leads

Dirty electrodes and leads

Clean electrode leads.

Eroded electrode tips

Cl

l

t d ti

d

t

Improper electrode gap spacing

Clean electrode tips and reset

the gap to 5/32 inches and cor-

Ignition Electrodes

Remove gun assembly and in-

spect electrodes and leads.

Improper position of electrode

tips

the gap to 5/32 inches and cor

rectly position tips.

Bad buss bar connection

Retension and realign.

Cracked or chipped insulators

Replace electrode.

Cracked or burned lead insula-

tors

Replace electrode leads.

I

iti

Connect ignition leads to the

t

f

St t b

d b

Low line voltage

Check voltage at power source.

Correct cause of voltage drop

or call the power company.

Ignition

Transformer

g

transformer. Start burner and ob-

serve spark. Check line voltage

to transformer primary.

Burned out transformer wind-

ings.

Replace the transformer.

to transformer primary.

No spark or weak spark

Properly ground the transformer

case.

B

M t

Motor does not come up to

speed and trips out on overload.

T

ff

d

t t bl

Low line voltage

Check voltage at power source.

Correct cause of voltage drop

or the call power company.

Burner Motor

p

p

Turn off power and rotate blower

wheel by hand to check for bind-

ing or excessive drag.

Pump or blower overloading

motor

Correct cause of overloading.

ing or excessive drag.

Faulty motor

Replace motor.

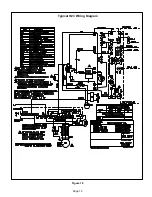

Содержание O23

Страница 15: ...Page 15 Figure 18 Typical O23 Wiring Diagram...