Page 10

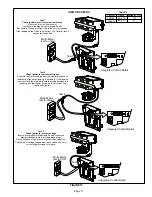

4. Integrated Ignition Control 103085 (A92)

WARNING

Shock hazard.

Disconnect power before servicing. Control is not

field repairable. If control is inoperable, simply re

place entire control.

Can cause injury or death. Unsafe operation will re

sult if repair is attempted.

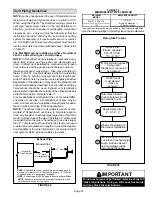

The hot surface ignition control system consisting of an in

tegrated control (figure 6 with control terminal designations

in tables 4 and 5), flame sensor and ignitor (figure 10). The

integrated control and ignitor work in combination to en

sure furnace ignition and ignitor durability. The integrated

control, controls all major furnace operations. The inte

grated control also features a RED LED for troubleshooting

and two accessory terminals rated at (1) one amp. See

table 6 for troubleshooting diagnostic codes. The 120V ig

nitor is made from a high strength, silicon nitride material

that provides long life and trouble free maintenance.

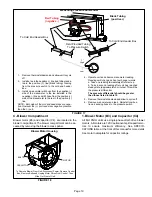

Electronic Ignition (Figure 7)

On a call for heat the integrated control monitors the com

bustion air inducer pressure switch. The control will not be

gin the heating cycle if the pressure switch is closed (by-

passed). Once the pressure switch is determined to be

open, the combustion air inducer is energized. When the

differential in the pressure switch is great enough, the pres

sure switch closes and a 15-second pre-purge begins. If

the pressure switch is not proven within 2-1/2 minutes, the

integrated control goes into Watchguard-Pressure Switch

mode for a 5-minute re-set period.

After the 15-second pre-purge period, the ignitor warms up

for 20 seconds after which the gas valve opens for a 4-sec

ond trial for ignition. The ignitor remains energized for the

first 3 seconds of the 4 second trial for ignition. If ignition is

not proved during the trial for ignition, the integrated control

will try four more times with an inter purge and warm-up

time between trials of 30 seconds. After a total of five trials

for ignition (including the initial trial), the integrated control

goes into Watchguard-Flame Failure mode. After a

60-minute reset period, the integrated control will begin the

ignition sequence again.

TABLE 4

4-Pin Terminal Designation

PIN #

FUNCTION

1

Combustion Air Inducer Line

2

Ignitor Line

3

Combustion Air Inducer Neutral

4

Ignitor Neutral

TABLE 5

12-Pin Terminal Designations

PIN #

FUNCTION

1

High Limit Output

2

Sensor

3

24V Line

4

Not Used

5

Rollout Switch Out

6

24V Neutral

7

High Limit Input

8

Ground

9

Gas Valve Common

10

Pressure Switch In

11

Rollout Switch In

12

Gas Valve Out

TABLE 6

DIAGNOSTIC CODES

LED Status

DESCRIPTION

LED Off

No power to control or control harware

fault detected.

LED On

Normal operation.

1 Flash

Flame present with gas vavle

de-energized.

2 Flashes

Pressure switch closed with combustion

air inducer de-energized.

3 Flashes

Pressure switch open with combus

tion air inducer energized.

4 Flashes

Primary limit switch open.

5 Flashes

Rollout switch open.

6 Flashes

Pressure switch cycle lockout.

7 Flashes

Lockout, burners fail to light.

8 Flashes

Lockout, buners lost flame too many

times.

9 Flashes

Line voltage polarity incorrect.

Note - This control is equipped with a push button switch for

diagnostic code recall. The control stores the last 5 fault

codes in non-volatile memory. The most recent fault code

is flashed first, the oldest fault code is flashed last. There is

a 2 second pause between codes. When the push button

switch is pressed for less than 5 seconds, the control will

flash the stored fault codes when the switch is released.

The fault code history may be cleared by pressing the push

button switch for more than 5 seconds.