Page 37

Electrical

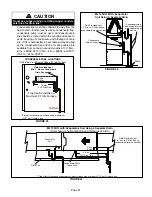

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic com-

ponents. Take precautions during furnace installa-

tion and service to protect the furnace’s electronic

controls. Precautions will help to avoid control ex-

posure to electrostatic discharge by putting the fur-

nace, the control and the technician at the same

electrostatic potential. Neutralize electrostatic

charge by touching hand and all tools on an un-

painted unit surface, such as the gas valve or blower

deck, before performing any service procedure.

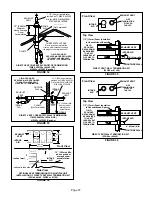

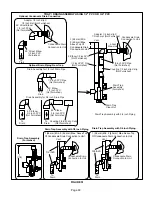

INTERIOR MAKE−UP BOX INSTALLATION

FIGURE 55

MAKE−UP

BOX

Left side

INTERIOR MAKE−UP BOX INSTALLATION

FIGURE 56

MAKE−UP

BOX

Right Side

remove and relocate

plug to unused

opening on left side

The unit is equipped with a field make−up box. The make−

up box may be moved to the right side of the furnace to fa-

cilitate installation. Seal unused openings on left side with

plugs removed from right side. Secure the excess wire to

the existing harness to protect it from damage.

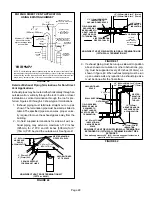

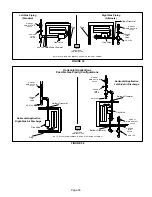

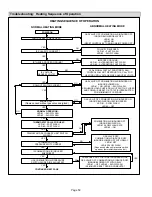

Refer to figure 58 for field wiring and figure 59 for schematic

wiring diagram and troubleshooting.

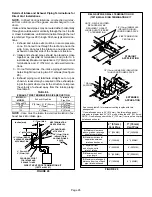

The power supply wiring must meet Class I restrictions.

Protected by either a fuse or circuit breaker, select circuit

protection and wire size according to unit nameplate.

NOTE −

Unit nameplate states maximum current draw.

Maximum Over−Current Protection allowed is 15 AMP.

Holes are on both sides of the furnace cabinet to facilitate

wiring.

Install a separate (properly sized) disconnect switch near

the furnace so that power can be turned off for servicing.

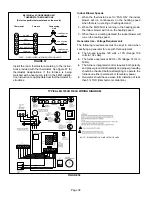

Before connecting the thermostat check to make sure the

wires will be long enough for servicing at a later date. Make

sure that thermostat wire is long enough to facilitate future

removal of blower for service.

Complete the wiring connections to the equipment. Use the

provided unit wiring diagram and the field wiring diagram

shown in figure 58. Use 18−gauge wire or larger that is suit-

able for Class II rating for thermostat connections.

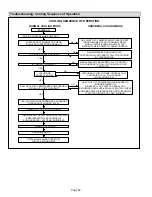

Electrically ground the unit according to local codes or, in

the absence of local codes, according to the current Na-

tional Electric Code (ANSI/NFPA No. 70) for the USA and

current Canadian Electric Code part 1 (CSA standard

C22.1) for Canada. A green ground wire is provided in the

field make−up box.

NOTE − The ML195UH furnace contains electronic compo-

nents that are polarity sensitive. Make sure that the furnace

is wired correctly and is properly grounded.

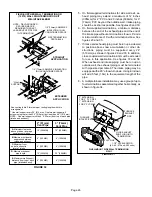

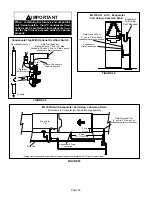

Accessory Terminals

One line voltage EAC" 1/4" spade terminal is provided on

the furnace integrated control. See figure 60 for integrated

control configuration. This terminal is energized when the

indoor blower is operating. Any accessory rated up to one

amp can be connected to this terminal with the neutral leg

of the circuit being connected to one of the provided neutral

terminals. If an accessory rated at greater than one amp is

connected to this terminal, it is necessary to use an exter-

nal relay.

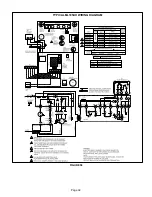

One line voltage HUM" 1/4" spade terminal is provided on

the furnace integrated control. See figure 60 for integrated

control configuration. This terminal is energized in the

heating mode when the combustion air inducer is operat-

ing. Any humidifier rated up to one amp can be connected

to this terminal with the neutral leg of the circuit being con-

nected to one of the provided neutral terminals. If a humidi-

fier rated at greater than one amp is connected to this termi-

nal, it is necessary to use an external relay relay.