Page 22

REGULATOR

COVER SCREW

FIGURE 35

WHITE RODGERS 36E GAS VALVE

REGULATOR ADJUSTMENT SCREW LOCATION

ADJUSTING

SCREW

Manifold Pressure Measurement & Adjustment

NOTE - Pressure test adaptor kit (10L34) is available from

Lennox to facilitate manifold pressure measurement.

1 - Connect test gauge to outlet tap on gas valve.

2 - Disconnect pressure sensing hose from gas valve and

plug hose by covering opening with tape or equivalent.

Leave barbed fitting on valve open to atmosphere.

See figure 36.

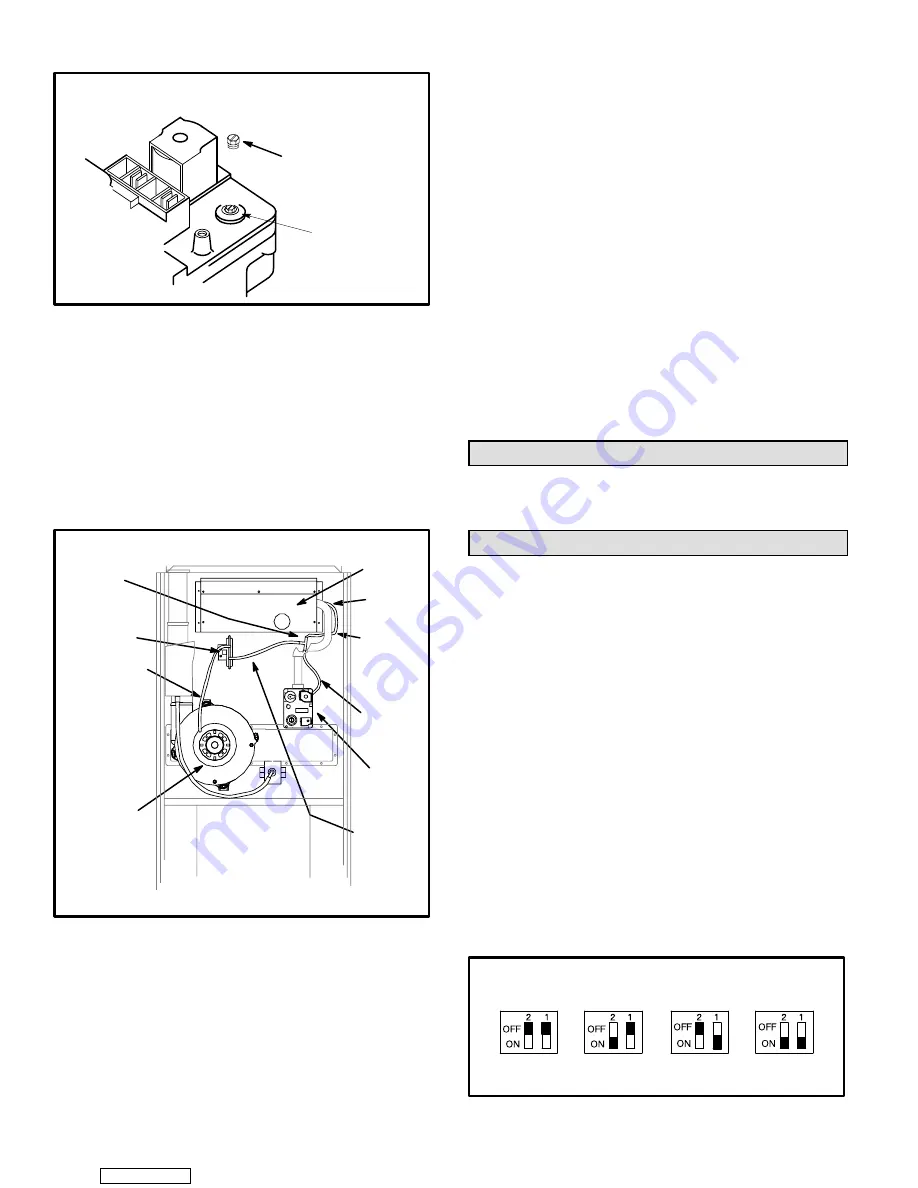

FIGURE 36

DIFFERENTIAL PRESSURE SWITCH CIRCUITRY

BURNER

BOX

GAS

VALVE

SENSING

HOSE

COMBUSTION

AIR PRESSURE

SENSING HOSE

COMBUSTION

AIR INDUCER

BURNER

BOX

SENSING

HOSE

GAS

VALVE

TEE

PRESSURE

SWITCH

SENSING

HOSE

HOSE

BARB

DIFFERENTIAL

PRESSURE

SWITCH

LEFT SIDE OF PRESSURE SWITCH = MORE NEGATIVE

RIGHT SIDE OF PRESSURE SWITCH = LESS NEGATIVE (Closer to Zero)

3 - Start unit and allow 5 minutes for unit to reach steady

state.

4 - Examine the burner flame. The flame should be stable

and should not lift from the burner. Natural gas should

burn blue. L.P./propane gas should burn mostly blue

with some orange streaks.

5 - After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to values given in

table 6.

NOTE - Shut unit off and remove manometer as soon as an

accurate reading has been obtained. Take care to replace

pressure tap plug.

NOTE - During this test procedure, the unit unit will be over-

firing:

D

Operate unit only long enough to obtain accurate reading to

prevent overheating heat exchanger.

D

Attempts to clock gas valve during this procedure will be

inaccurate. Measure gas flow rate only during nor-mal

unit operation.

6 - When test is complete remove obstruction from hose

and return hose to gas valve barbed fitting.

Gas Flow

To check for proper gas flow to the combustion chamber, deĆ

termine the Btu (kW) input from the unit rating plate. Divide

this input rating by the Btu (kW) per cubic foot (cubic meter)

of available gas. The result is the required number of cubic

feet (cubic meter) per hour. Determine the flow of gas

through the gas meter for two minutes and multiply by 30 to

get the hourly flow of gas.

High Altitude Information

Unit does not need gas pressure adjustment when operating

from 0 to 7500 feet (0 to 2248m). See table 6 for correct manĆ

ifold pressures for LP/propane and natural gases.

Other Unit Adjustments

Natural to LP/Propane Changeover

A natural gas to LP/propane gas changeover kit is required

to convert unit. Refer to installation instructions supplied

with kit for conversion procedure.

Heat Anticipation Settings

Thermostat anticipator setting (if adjustable) should be set

according to amps listed on wiring diagram on unit.

Flame Rollout Switch

Factory set: No adjustment necessary.

Limit Control

Factory set: No adjustment necessary.

Pressure Switch

Factory set: No adjustment is necessary.

Fan Control

The fan-on delay of 45 seconds is not adjustable. The fan-

off delay (time that the blower operates after the heating

demand has been satisfied) can be adjusted by moving the

jumper on the SureLight

t

integrated control. The unit is

shipped with a factory fan-off delay of 90 seconds. The fan-

off delay will affect comfort and is adjustable to satisfy indiĆ

vidual applications. See figure 37.

FIGURE 37

FANĆOFF TIME ADJUSTMENT

To adjust fan-off timing, flip dip switch to desired setting.

60sec.

90sec.

120sec.

180sec.

Downloaded from