Page 19

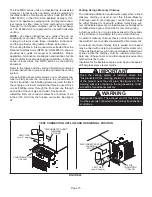

TABLE 4

Vent Connector Capacity

Type B Double-Wall Vents with Type B Double-Wall Connectors

Serving Two or More Category I Appliances

Height

H

(feet)

Lateral

L

(feet)

Vent and Connector Diameter - D (inches)

3 inch

4 inch

5 inch

6 inch

Appliance Input Rating in Thousands of Btu Per Hour

Min

Max

Min

Max

Min

Max

Min

Max

6

1

22

37

35

66

46

106

58

164

2

23

41

37

75

48

121

60

183

3

24

44

38

81

49

132

62

199

8

1

22

40

35

72

49

114

64

176

2

23

44

36

80

51

128

66

195

3

24

47

37

87

53

139

67

210

10

1

22

43

34

78

49

123

65

189

2

23

47

36

86

51

136

67

206

3

24

50

37

92

52

146

69

220

15

1

21

50

33

89

47

142

64

220

2

22

53

35

96

49

153

66

235

3

24

55

36

102

51

163

68

248

20

1

21

54

33

99

46

157

62

246

2

2

57

34

105

48

167

64

259

3

23

60

35

110

50

176

66

271

30

1

20

62

31

113

45

181

60

288

2

21

64

33

118

47

190

62

299

3

22

66

34

123

48

198

64

309

TABLE 5

Common Vent Capacity

Type B Double-Wall Vents with Type B Double-Wall Connectors

Serving Two or More Category I Appliances

Vent

Height

H

(feet)

Vent and Connector Diameter - D (inches)

4 inch

5 inch

7 inch

7 inch

Appliance Input Rating in Thousands of Btu Per Hour

FAN + FAN

FAN + NAT

FAN + FAN

FAN + NAT

FAN + FAN

FAN + NAT

FAN + FAN

FAN + NAT

6

92

81

140

116

204

161

309

248

8

101

90

155

129

224

178

339

275

10

110

97

169

141

243

194

367

299

15

125

112

195

164

283

228

427

352

20

136

123

215

183

314

255

475

394

30

152

138

244

210

361

297

547

459