Page 11

9. Combustion Air Inducer (B6)

All EL180UHNE units use a combustion air inducer to

move air through the burners and heat exchanger during

heating operation. The blower uses a 120VAC motor. The

motor operates during all heating operation and is con

trolled by integrated control A92. The inducer also oper

ates for 15 seconds before burner ignition (pre‐purge) and

for 5 seconds after the gas valve closes (post‐purge).

10. Combustion Air Inducer Prove Switch (S18)

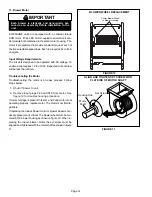

EL180UHNE series units are equipped with a combustion

air pressure switch (figure 7) located near the gas valve. The

switch is connected to the combustion air inducer housing

by means of a flexible silicone hose. It monitors negative air

pressure in the intake air elbow.

The switch is a single‐pole single‐throw proving switch elec

trically connected to the furnace control. The purpose of the

switch is to prevent burner operation if the combustion air in

ducer is not operating or if the flue becomes obstructed.

On heat demand the switch senses that the combustion air

inducer is operating. It closes a circuit to the integrated con

trol when pressure inside the combustion air inducer de

creases to a certain set point. The pressure sensed by the

switch is negative relative to atmospheric pressure. If the

flue becomes obstructed during operation, the switch

senses a loss of pressure difference and opens the circuit

to the furnace control and gas valve. See table 6 for set

point.

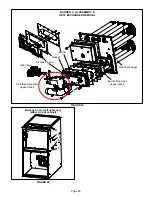

If replacing the inducer switch or tubing is necessary, make

note of the tubing connections to the gas valve. See figure

8.

NOTE -

The switch is factory set and is not field adjustable.

It is a safety shut‐down control in the furnace and must not

be by-passed for any reason. If switch is closed or by-

passed, the control will not initiate ignition at start up.

TABLE 6

Prove Switch Set Points

EL180

Model

Make inches w.c.

Break inches w.c.

040

0.35

0.20

060

0.35

0.20

080

0.35

0.20

100

0.35

0.20

FIGURE 7

COMBUSTION AIR PRESSURE SWITCH

Po

to air intake pipe

Negative -

to air intake

elbow

11. Burner and Orifice

Burners are factory set and require no adjustment. Always

operate the unit with air gas plenum in place. The burner

has one orifice located between the gas valve and the air

intake assembly (Figure 6). To check or replace the orifice

remove the intake air screen, coupling and intake air elbow.

Using a 5/8” socket, go through the elbow and unscrew the

gas orifice. The burner uses an orifice (see Table 7) that is

precisely matched to the burner input. The burner can be

removed for service. If burner has been removed, it is criti

cal to replace all gaskets.

TABLE 7

Gas Orifice Nat Gas

Unit Input

Orifice Size

40

0.0595

60

0.0595

80

0.0689

100

0.0810

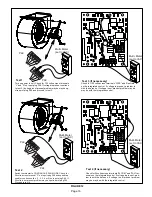

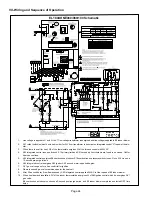

The SureLight® ignitor is made of durable silicon nitride. Ig

nitor longevity is enhanced by controlling voltage to the ig

nitor. The integrated control provides a regulated 120 volts

to the ignitor for a consistent ignition and long ignitor life.

Ohm value should be 39 to 70.

See figure 9 for resistance, and voltage check.

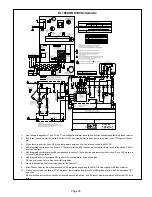

NOTE - The EL180UHNE furnace contains electronic

components that are polarity sensitive. Make sure that the

furnace is wired correctly and is properly grounded.