Page 29

FIGURE 19

HORIZONTAL

DRAIN PAN*

UPFLOW/

DOWNFLOW

DRAIN PAN

DOWNFLOW DISCHARGE CONFIGURATION

*FOR OPTIMUM

PERFORMANCE,

REMOVE

HORIZONTAL

DRAIN PAN.

4− Rotate cabinet 180

_

from upright. It may be

necessary to first remove the blower assembly to

lighten the cabinet for lifting.

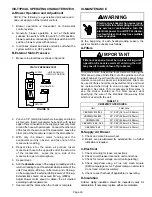

5− Install downflow drip shield firmly in place on inside of coil

slab from under drain pan. See figures 20 and 21.

1

2

side view

1− Apply two pieces of foam tape (provided)

down both ends of each shield. The tape

should measure 4 3/4" X 2" (120 X 25 mm).

Ensure that the tape covers both sides of the

shield equally.

2− Apply the longer piece of foam tape between

the pieces on each end. This piece of tape is

1" wide.

FIGURE 20

DOWNFLOW DRIP SHIELDS

Coil

Drip Shield

Drip Pan

FIGURE 21

6− Replace coil assembly and blower if removed.

Replace coil access panel. If horizontal drain pan is not

removed, depress tab in cabinet support rail to hold

horizontal drain pan in place. See figure 19.

7− Set unit so that it is level. Connect return and supply air

plenums as required using sheet metal screws.

NOTE−For downflow application, metal or class I supply

and return air plenums must be used.

For downflow installation on combustible flooring, an

additive base must be used. See figure 22.

FIGURE 22

COMBUSTIBLE

FLOOR

ADDITIVE BASE

PROPERLY SIZE

FLOOR OPENING

BLOWER

COIL UNIT

Cut an opening appropriately sized for combustible base. Base

dimensions are shown in figure 23. After opening has been cut,

set the additive base into opening. Connect outlet air plenum to

the additive base. Set the unit on the additive base so flanges

of the unit drop into the base opening and seal against the

insulation strips. Seal around the insulation strips with

permagum. The unit is now locked in place. Install return air

plenum and secure with sheet metal screws.