Page 21

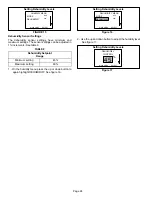

V− OPTIONAL HUMIDITY CONTROL (A20)

COVER

VERTICAL SLIDE CONTROL

(control setpoint)

SLIDE

(ON CIRCUIT BOARD)

TERMINAL BLOCK

HINGES

BASE SECTION

INDICATING LIGHTS

Efficiency

Plus

PARTS IDENTIFICATION

NOTE−TO REMOVE COVER, HOLD BASE SECTION

AND GENTLY PULL THE COVER OUT AT THE BOT-

TOM AND PIVOT IT UP AND AWAY FROM BASE.

FIGURE 11

CONTROL WIRE ENTRY

HUMIDITY SENSOR

A−CCB1

Optional Comfort Control Board (CCB1) A20 may be

installed adjacent to the indoor thermostat (figure 11). The

control monitors indoor humidity conditions and creates a

dehumidification demand in response to indoor humidity

just as the thermostat creates a cooling demand in

response to indoor temperature. The CCB1 works in

combination with the indoor thermostat to adjust

compressor speed and indoor blower speed. Although the

control provides a dehumidification demand, only the

thermostat can directly control compressor operation. The

CCB1 cannot call for a compressor cycle by itself.

Principles of Cooling with Drier Air

The humidity comfort range for humans is between 40%

and 60% relative humidity (RH). A vertical slide on the

control allows the humidity setpoint to be adjusted within

that comfort range. 50% RH is the recommended initial

setpoint until personal comfort level is established. The

personal comfort level will vary with humidity as with

temperature. For example, if air at 75

°

F and 50% RH is

changed to 60% RH, the air will feel" much warmer.

Likewise, if the air is reduced to 40% RH, it will feel" much

cooler.

Even when inactive, the body evaporates a large amount of

moisture away from the skin. This evaporation produces a

cooling effect (during wintertime this phenomenon is called

wind-chill"). Dry air is capable of absorbing more moisture

away from the skin thereby increasing the cooling effect.

When the CCB1 senses that the indoor humidity level is

above the control setpoint, the control places the

CBX32MV and outdoor unit in a dehumidification mode .

To produce drier air, the CBX32MV will slow down the

speed of the air crossing the indoor coil. Because the air is

moving much slower than normal, the indoor coil is allowed

more time to remove moisture from the air (a higher

percentage of the air passing over the coil is cooled to its

dew point removing more moisture). At the same time the

two-speed outdoor unit will switch to high-speed to produce

a colder indoor coil. The colder indoor coil and slower

moving air combine to produce drier supply air.

NOTE−The indoor blower speed is reduced in order to

slow the air speed across the indoor coil. The supply air

exiting the unit may not feel as forceful. This is normal.

Remember that when the unit is in dehumidification

mode, the comfort level is increased because the unit is

producing cooler, drier air.

The exact sequence of operation to produce cooler, drier air

is described in the following section.

Operation

The CCB1 operates only during cooling mode. During

normal cooling operation, when there is no indoor humidity

demand, the unit operates as a straight two-speed cooling

system. First stage thermostat demand energizes the

compressor and indoor blower on low speed. Increased

cooling demand energizes the compressor and indoor

blower on high speed.

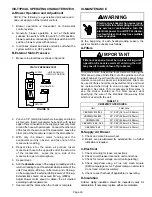

The control is equipped with a row of orange LED lights on

its face which indicate the amount of relative humidity

demand present. When one or more LEDs are lit, the

control signals the CBX32MV to begin dehumidification

mode. Tables 10 and 11 shows system response to

thermostat and CCB1 demand.

Calibration Precautions

Extreme care should be taken to avoid exposing the CCB1

to fumes from household chemicals. The humidity sensing

element in the CCB1 is a precise component which can be

damaged or the calibration changed by household

chemicals and cleaning agents. Make sure all household

chemicals are stored in a different room in the building.

Also, use only mild diluted soapy water when cleaning the

CCB1 cover or the area surrounding the CCB1. The

sensing element cannot be field calibrated. The CCB1

contains no field repairable parts and must be replaced

when damaged in this manner.

Agents which can damage the CCB1 include alcohol,

benzene, chlorine and chlorine based solutions, acetone

(nail polish remover), bug sprays and other household

cleaners.

Calibration can also be adversely affected by the

placement of the CCB1 with respect to the indoor

thermostat, exterior doors and windows and supply air

registers. Most thermostats have anticipation resistors