507281-06

Page 15 of 58

Issue 1724

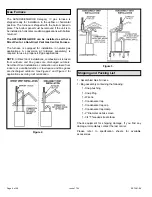

Joint Cementing Procedure

Use PVC primer and solvent cement or ABS solvent

cement meeting ASTM specifications; refer to Table 2. As

an alternate, use all purpose cement to bond ABS, PVC, or

CPVC pipe when using fittings and pipe made of the same

materials. Use transition solvent cement when bonding

ABS to either PVC or CPVC.

Low temperature solvent cement is recommended during

cooler weather. Metal or plastic strapping may be used for

vent pipe hangers. Uniformly apply a liberal coat of PVC

primer for PVC or use a clean dry cloth for ABS to clean

inside socket surface of fitting and male end of pipe to

depth of fitting socket.

Canadian Applications Only

Pipe, fittings, primer and solvent cement used to vent

(exhaust) this appliance must be certified to ULC S636 and

supplied by a single manufacturer as part of an approved

vent (exhaust) system. When bonding the vent system to

the furnace, use ULC S636 approved One-Step Transition

Cement to bond the pipe to the flue collar, or to bond

the 90° elbow or reducing 90° elbow to the flue collar. In

addition, the first three feet of vent pipe from the furnace

flue collar must be accessible for inspection.

All cementing of joints should be done according to the

specifications outlined in ASTM D 2855.

DANGER OF EXPLOSION!

Fumes from PVC glue may ignite during system check.

Allow fumes to dissipate for at least 5 minutes before

placing unit into operation.

DANGER

1. Measure and cut vent pipe to desired length.

2. Debur and chamfer end of pipe, removing any ridges

or rough edges. If end is not chamfered, edge of pipe

may remove cement from fitting socket and result in a

leaking joint.

3. Clean and dry surfaces to be joined.

4. Test fit joint and mark depth of fitting on outside of pipe.

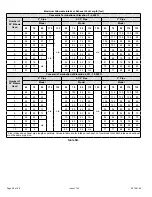

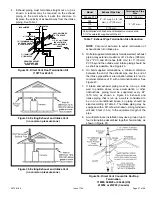

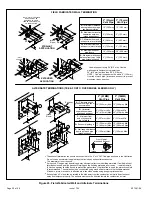

Table 3. Outdoor Termination Kits Usage

Model

VENT

PIPE DIA.

(in.)

STANDARD

CONCENTRIC

Outdoor Exhaust

Accelerator

(Dia. X Length)

Outdoor

Exhaust

Accelerator

(Dia. X Length)

Flush

Mount Kit

1-1/2”

Concentric

Kit

2”

Concentric

Kit

3”

Concentric

Kit

1-1/2” X 12”

2” X 12”

51W11**

71M80

or

†

44W92

††

69M29

or

†

44W92

††

60L46

or 44W93

†

045

2

YES

YES

YES

2-1/2

YES

YES

YES

3

YES

YES

YES

070

2

YES

YES

YES

2-1/2

YES

YES

YES

3

YES

YES

YES

090

2

YES

YES

YES

YES

2-1/2

YES

YES

YES

YES

3

YES

YES

YES

YES

110

2

YES

YES

YES

YES

2-1/2

YES

YES

YES

YES

3

YES

YES

YES

YES

135

3

YES

YES

YES

* Requires field-provided and installed 1-1/2” exhaust accelerator.

** Kit 51W11 is provided with a 1-1/2” accelerator, which must be for all 2 and 2-1/2” PVC installations.

† Termination kits 44W92 and 44W93, 30G28 and 81J20 are approved for use in Canadian installations to meet CSAB149 and ULC

S636.

†† The 44W92 Concentric kit is provided with a 1-1/2” accelerator, which must be installed on the exhaust outlet when this kit is used

with this furnace.

Содержание 95G2UHE

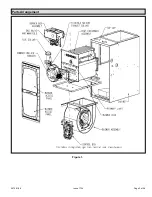

Страница 3: ...507281 06 Page 3 of 58 Issue 1724 Figure 1 Parts Arrangement...

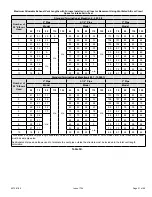

Страница 45: ...507281 06 Page 45 of 58 Issue 1724 Table 13A Field Wiring Applications With Conventional Thermostat...

Страница 46: ...507281 06 Page 46 of 58 Issue 1724 Table 13B Field Wiring Applications With Conventional Thermostat Continued...

Страница 49: ...507281 06 Page 49 of 58 Issue 1724 Figure 66...