7

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

LENNOX HEARTH PRODUCTS • MERIT PLUS

®

B-VENT GAS FIREPLACES (MPB33/35/40/45) • CARE AND OPERATION INSTRUCTIONS

NOTICE:

A white film may develop

on the glass enclosure panel during

the first few fires as part of the burn-in

process.

The first few times you use the

fireplace, clean the glass after each use

(

AFTER THE GLASS HAS COMPLETELY

COOLED

); otherwise, the white film

will bake onto the glass and become

difficult to remove.

See glass cleaning instructions on

Page 11

.

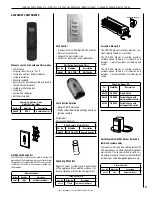

Manifold Gas Supply Pressure

Fuel #

Low

High

Natural

Gas

2.2" WC

(0.55 kPa)

3.5" WC

(0.87 kPa)

Propane

6.3" WC

(1.57 kPa)

10.0" WC

(2.49 kPa)

Table 3

Test gauge connections are provided on the

front of the millivolt and electronic gas control

valve (identified IN for the inlet and OUT for the

manifold side). The control valves have a 3/8"

(10mm) NPT thread inlet and outlet side of the

valve (refer to

Figures 2 and 3

)

.

Propane tanks are at pressures that will cause

damage to valve components. Verify that the

tanks have step down regulators to reduce the

pressure to safe levels.

These appliances comply with National Safety

Standards and are tested and listed by OMNI-

Test Laboratories, Inc. (Report No. 116-F-36d-5)

to ANSI Z21.50b-2009 (in Canada, CGA 2.22b-

2009), and CAN/CGA-2.17-M91 (R2009) in

both USA and Canada, as vented gas fireplaces.

The Installation must conform to local codes

or, in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1 / NFPA 54

- latest edition, or the Natural Gas and Propane

Installation Code, CAN/CGA B149.1 - latest

edition. The appliance, when installed, must be

electrically grounded in accordance with local

codes or, in the absence of local codes, the latest

edition of the National Electrical Code, ANSI/NFPA

70, or the Canadian Electrical Code,

CGA C22.1 - latest editions.

BTU Input

Millivolt appliances are manually controlled

and feature a spark igniter (piezo) that allows

the appliance pilot gas to be lit without the use

of matches or batteries. This system provides

continued service in the event of a power outage.

Both millivolt and electronic systems can be

operated during a power outage, and feature

manually operated hi-low flame control. The BTU

Input for these appliances is shown in

Table 1.

Input (BTU/HR) Gas Valves

Models

Nat. Gas

Prop. Gas

Input Rate

(BTU/HR

Input Rate

(BTU/HR

MPB33

13,500 to

17,500

13,500 to

17,500

MPB35

16,000 to

20,000

16,500 to

20,000

MPB40

24,000 to

30,000

22,300 to

28,000

MPB45

24,750 to

31,000

23,000 to

29,000

Table 1

Gas Pressure Requirements

Tables 2 and 3

show the appliance inlet and

manifold gas pressure requirements.

Inlet Gas Supply Pressure

Fuel #

Minimum

Maximum

Natural

Gas

4.5" WC

(1.12 kPa)

10.5" WC

(2.62 kPa)

Propane

11.0" WC

(2.74 kPa)

13.0" WC

(3.24 kPa)

Table 2

The appliance and its appliance main gas

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures

in

excess of

1/2 psi (3.5 kPa).

The appliance must be isolated from the gas

supply piping system by closing its equipment

shutoff valve during any pressure testing of

the gas supply piping system at test pressures

equal to or less than

1/2 psi (3.5 kPa).

Orifice Sizes - Sea Level to High Altitude

(All Models)

These appliances are tested and approved for

installation at elevations of 0-4500 feet (0-1372

meters) above sea level using the standard

burner orifice sizes (marked with an "*" in

Table

4

)

. For elevations above 4500 feet, contact your

gas supplier or qualified service technician.

Deration -

At higher elevations, the amount

of BTU fuel value delivered must be reduced

by either:

• Using gas that has been derated by the gas

company.

• Changing the burner orifice to a smaller size

as regulated by the local authorities having

jurisdiction and by the (USA) National Fuel

Gas Code NFPA 54/ANSI Z223.1 - latest

edition or, in Canada, the CAN/CGA-B149.1

codes - latest edition.

Install the appliance according to the regulations

of the local authorities having jurisdiction and,

in the USA, the National Fuel Gas Code NFPA

54 / ANSI Z223.1 - latest edition or, in Canada,

the CAN/CGA-B149.1 - latest edition.

Flame breadth, height and width will diminish

4% for every 1,000 feet of altitude.

In Canada - CAN/CGA-2.17-M91 (R2009)

(high altitude):

THE CONVERSION SHALL BE CARRIED

OUT BY A MANUFACTURER’S AUTHO-

RIZED REPRESENTATIVE, IN ACCOR-

DANCE WITH THE REQUIREMENTS OF

THE MANUFACTURER, PROVINCIAL OR

TERRITORIAL AUTHORITIES HAVING

JURISDICTION AND IN ACCORDANCE

WITH THE REQUIREMENTS OF THE

CAN/CGA-B149.1 OR CAN/CGA-B149.2

INSTALLATION CODES.

Burn-in Period

During the first few fires in this appliance there

will be some odor due to the curing of the

paint and burning off of lubricants used in the

manufacturing process. Depending on your

use, the burn-in period may take a few hours

or a few days.

KEEP YOUR HOUSE WELL VENTILATED

DURING THE CURING PROCESS. THE ODOR

AND HAZE EMITTED DURING THE CURING

PROCESS CAN BE QUITE NOTICEABLE AND

MAY SET OFF A SMOKE DETECTOR.

If an optional blower is installed, do not turn it

on during the burn-in period.

Burner Orifice Sizes

Elevation 0-4500 feet ( 0-1372 meters)

Model

Nat.Gas

drill size (inches)

Propane

drill size (inches)

MPB33

#47 (0.0785")*

99K74•

(0.048")*

99K78•

MPB35

#44 (0.086")*

60J80•

#55 (0.052")*

19L52•

MPB40

#38 (0.102")*

99K76•

(0.062")*

21L01•

MPB45

#37 (0.104")*

24M10•

#52 (0.0635")*

37G00•

Table 4

* Standard size installed at factory

• Part /Cat. Number