innovators in agriculture

EN-6

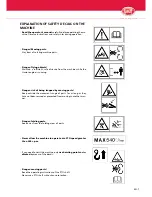

SAFETY INSTRUCTIONS

- Use the machine only for the purpose for which it was designed.

- Follow all prevailing safety regulations, including those laid down

in this manual and indicated on the machine.

- Operate this machine in a safe manner.

- The machine should be operated by authorised persons only.

- Be alert and observe all safety precautions.

- Ensure that all safety guards and protection devices are in place.

- Keep out of reach of moving parts.

- Stop the engine, PTO and moving parts before adjusting, cleaning

or lubricating the machine.

- Take care that nobody is within the dangerous zone while the ma-

chine is in operation and ensure that people are kept well away

from the machine. This is especially important when working

along roads and near or on fields that are accessible to the public.

- Always use a tractor with a cab.

- Clear the field of any objects that could be thrown up by the ma-

chine.

- Observe prevailing legislation for public road transport.

- Use flashing lights or other safety signs, when required.

- Do not stand on the machine.

- Use genuine LELY parts only.

- Remove the pressure from hydraulic systems before starting work

on them and/or before coupling/uncoupling hydraulic hoses.

- Use protective clothing, gloves and/or safety glasses if required.

- Clean the safety decals regularly so that they can be read at all

times.

Содержание LOTUS 1020 Profi

Страница 2: ...innovators in agriculture ...

Страница 4: ...EN 2 innovators in agriculture ...

Страница 6: ...EN 4 innovators in agriculture ...