innovators in agriculture

EN-11

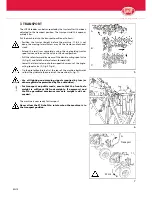

4 MACHINE ADJUSTMENTS

Ensure that no-one is near the machine when it is changed

from the transport position into the working position.

Put the machine into the working position as follows:

- Position the tractor straight before the machine. If this is not

done, the moving lateral rotors may hit the tractor and/or head-

stock.

- Fold the protection brackets at the rear of the machine forwards

(B, fig. 7).

Brackets that are not folded in can cause damage when the

machine is unfolded!

- Push the lateral rotors over the supports by means of the single-

acting spool valve (A, fig. 8).

- Fold out the lateral rotors (B, fig. 8) and lower the rotors onto the

ground by means of the double-acting spool valve (C).

- Place the double-acting spool valve in the floating position.

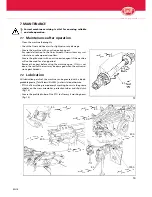

4.1

Tine adjustment

- Adjust the tines to the outer position (A, fig. 9).

For headland tedding:

Adjust the tines of the rotor on the plot side to the inner position

(B).

4.2

Rotor angle and working height

The wheels have the following preferred setting:

- LOTUS 900 (S): highest/second-to-highest position;

- LOTUS 1020 (S): second-to-highest/ middle position.

A more level machine adjustment may be required when handling

light crops or in windy conditions.

- Lift the rotors clear from the ground using the tractor's double-

acting hydraulic valve.

- Switch off the tractor engine and take the necessary precautions

to ensure the machine does not suddenly lower before you start

adjusting the wheel supports.

Adjust the wheels to the desired position (A, fig. 10).

For headland tedding:

Adjust the rotor on the plot side 1 position lower than the remain-

ing rotors.

- Lower the rotors.

- Adjust the working angle of the rotors in relation to the ground

via the spindle (B) in such a way that the tines gently sweep the

ground ensuring adequate crop pick-up. Rule of thumb: the tines

should touch the ground over a width of approximately 25 cm.

Deep adjustment causes an excessive load, which increases

wear and tear as well as the risk of tine breakage. The crop

will also become contaminated more easily.

Since the Lotus 900 and 1020 tedders can be equipped with narrow

or wide transport wheels, there are also two different basic settings

for the wheel assemblies. The correct setting is explained in appen-

dix B.

!

8

A

B

C

9

A

B

10

A

B

25 cm

!

Содержание LOTUS 1020 Profi

Страница 2: ...innovators in agriculture ...

Страница 4: ...EN 2 innovators in agriculture ...

Страница 6: ...EN 4 innovators in agriculture ...