7

PPR

REEPPA

AR

RIIN

NG

G TTH

HEE A

APPPPLLIIA

AN

NC

CEE

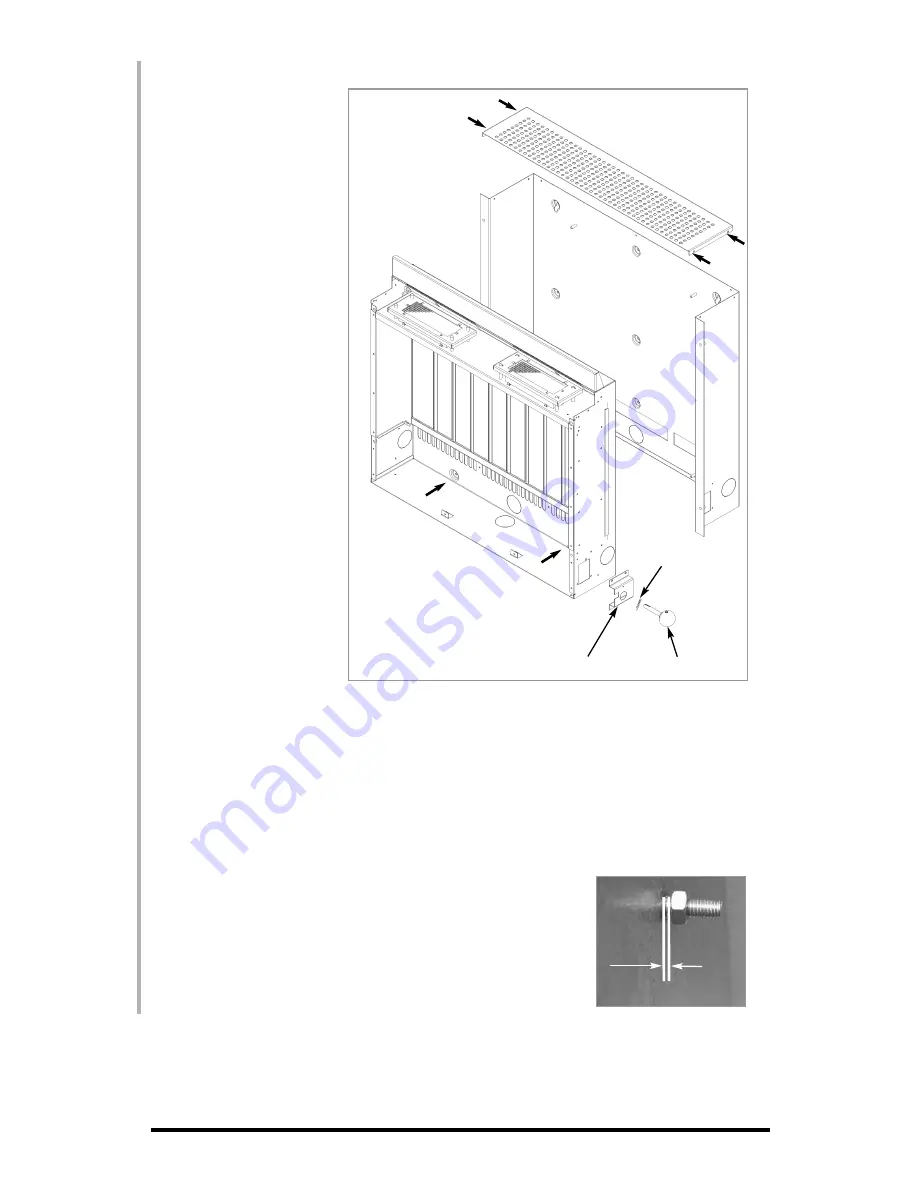

1. Firstly remove the two retaining

screws on each side of the upper

grille and remove the grille from

the outer casing.

2. Remove the two retaining nuts

from the retaining studs that pro-

trude into the lower part of the

main firebox as shown.

The control knob is located on the

lower right hand side of the outer

casing, and is mounted in an indi-

cator bracket, which has a metallic

indication ‘pip’. Both the knob and

the indicator bracket should be

removed as follows;

3. Remove the retaining pin from

the gas valve spindle and with-

draw the control knob and the

spindle extension from the right

hand side of the appliance.

4. Remove the four retaining

screws and the indicator bracket.

The main firebox may now be

detached from the outer casing.

FFIIXXIIN

NG

G TTH

HEE

A

APPPPLLIIA

AN

NC

CEE

After having selected the final

mounting position of the appli-

ance, taking into account the site

requirements as specified in sec-

tion 4 of these instructions, the

integrity of the wall, and the feasi-

bility of the proposed supply pipe

routing, the firebox of appliance

may be secured to the wall.

Due to the weight of the front

facia, it is possible to fix the outer

casing to the wall in up to nine

positions, depending on the

strength/condition of the wall. IIff iinn ddoouubbtt aallw

waayyss uussee eexxttrraa ffiixxiinnggss!!

If the appliance is to be mounted on the inner leaf of a conventional cavity wall, or a solid wall, drill four holes

using a 7mm masonry bit. Insert the fibre wallplugs provided.

If the appliance is to be mounted on a dry lined wall or a timber framed construction wall then special cavity

screw fixings will be required which are not supplied with this product. These should be constructed from metal

and not plastic.

Insert the screws into the upper two holes, leaving 5mm protruding from the wall. Temporarily hang the outer

casing on the wall, and mark any additional fixing points as required. Remove the outer casing from the wall and

drill holes for the additional fixing points as required. Insert either wall plugs or cavity screw fixings as required.

Re-position the outer casing on the wall and using a spirit level to check the casing is square and level, tighten

all of the fixing screws fully.

Now, with the outer casing fixed to the wall, the main firebox can be secured in

position. The firebox is held on the outer casing using four studs and four nuts.

Make sure that the upper nuts are un-screwed approximately one turn from the

fully tightened position in order to create a 2mm gap as shown. The firebox may

now be hung onto the top studs, and then pushed onto the lower studs so that

the lower studs protrude through the lower fixing holes in the back panel of the

firebox. Tighten the lower fixing nuts on to the lower fixing studs fully.

Next, re-fit the grille, the indicator bracket and the control knob and spindle, and

secure in position using the correct fixing screws (re-fitting is the opposite of

removal as detailed in section 7.0 of these instructions).

77..00

1. Remove the Grille

2. Remove retaining nuts

3. Remove spindle

retaining pin

4. Remove control indicator bracket and control knob

77..11

2mm