LAUNCH

Installation Instruction for Economical Symmetric Floor-plate 2-post Lift

2

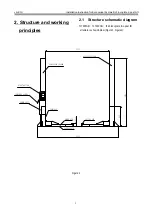

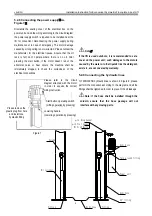

2. Structure and working

principles

2.1 Structure schematic diagram

TLT235SB

(

TLT240SB

)

the Floor-plate two-post lift

structure is shown below (Figure 1, Figure2):

SWING ARM

FLOOR PLATE

CARRIAGE

3370

min1

10

LIFTING PAD

POWERSIDE COLUMN

2750

278

0

80

0

LOWERING HANDLE

START BUTTON

POWER UNIT

OFFSIDE COLUMN

Figure 1