5

2. A 10 A fuse and fuse holder

3. Vehicle cable with at least 1.5 mm

²

cross-section

4. Fixture material and cable connector/shoe suitable for switch and relay

First locate a suitable position on the vehicle to mount the LED working light. There are two fixture options:

1)

Using the screw base.

Use the screw base as a drill template to drill holes for fixing the LED working light at

an appropriate location. Pay attention to ensure that you do not damage any hidden cables, wires or other

components when drilling. It is not permitted to drill holes in carrying parts of the chassis such as the

longitudinal cross members or roof frames.

a)

When you have made the holes, screw the LED working light firmly and securely to the vehicle (fixture

materials not included in the scope of delivery).

2)

Using the magnetic foot.

To do this, remove the pre-mounted screw base by unscrewing the two Allen screws

and the long hexagonal screw (from the hinge) on the underside of the LED working light. Now you can remove

the central hexagonal screw from below the screw base. To mount the magnetic foot, use the supplied 20 mm

long hexagonal screw with washer and nut with spring washer. Then connect the holder back up to the light

housing. To protect painted surfaces, glue the supplied rubber ring to the bottom of the magnetic foot. The LED

working light can now be placed on an even, magnetic surface.

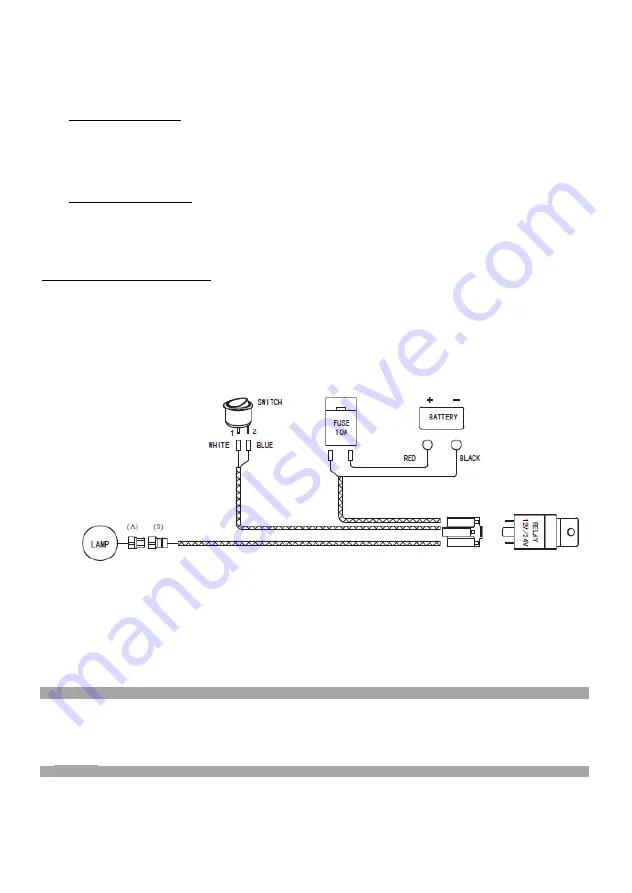

Connecting the LED working light

1.

First separate the battery from the on-board network of your vehicle. To do this, remove the ground cable

from the minus pole of the battery, usually labelled (-). To do this, read the manual of your vehicle or ask

your specialist workshop.

2.

Mount the switch in your vehicle at a location easy for the driver to access.

3.

Now connect the LED working light and the switch to the on-board network of your vehicle with the help of

the working current relay and a fuse (not included in the scope of delivery) in accordance with the sketch.

Pay attention to ensure that the cable you use has a sufficient cross-section.

Lay the cable without creating sharp bends and avoid running over sharp edges. Secure the wires firmly and without

exerting considerable force on the cable. Use the existing cable harnesses to secure the wires. If possible lay cables

behind cladding or under the floor carpets.

If you need to lay cables in the engine compartment of your vehicle make sure that sufficient space is left to avoid

moving parts such as belt pulleys, drive belts, drive and steering shafts as well as the wiper drives, and do not lay the

cable close to heat sources such as exhausts and catalytic converters.

After installation of the LED working light connect the battery up again.

Switch the LED working light on and check the functionality.

7. Maintenance

If used in accordance with the intended purpose, the device does not require maintenance. Clean the device carefully

with a dry cloth.

In the event of damages to the housing or cables, immediately disconnect the power supply to the device and contact

the manufacturer or your supplier.

8. Disposal

Packaging materials are raw materials and can be recycled. Please recycle in the interests of environmental

protection.