4

Instruction Manual

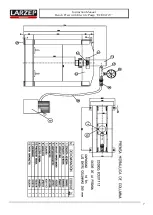

Bench Press with Electric Pump “ECE01113”

3.3

SAFETY PREVENTIVE ACTIONS AGAINST MECHANICAL RISKS

The construction of machine has been calculated to bear without any breaking under conditions of foreseen utilization and for the whole life of the machine. The

hydraulic components have been designed and calculated in compliance with the ANSI B30.1, and have been proved to 875Kg/cm

of pressing.

The frame of the machine does not cause to be dangerous in that sense.

3.4 SAFETY PREVENTIVE ACTIONS AGAINST OTHER RISKS

.

The machine is provided with a thermal relay to protect the motor.

The hydraulic pump is equipped with an internal security valve in the tank, out of operator’s control and rated at 700 Kg/cm

. The hydraulic cylinder is also furnisher

with a pressure relief valve, rated at 700 Kg/ cm

, which could be rated by the operator from 0 to 700 Kg/cm

.

3.5 MAINTENANCE

All the maintenance operations must be performed while the machine is stopped, thus avoiding this way any potentially dangerous situation. A poor maintenance

program of the press does not increase the risk, but obviously will revert in a lower performance.

The hydraulic pump is mounted out of the frame and access is very easy. To disassemble the pump unscrews the bolts in the tap cover. In order to disassemble the

cylinder it is required first to disassemble the piping and the cylinder from the frame.

ISOLATION OF POWER SUPPLY.

Release the cables of the terminal to disconnect the current tap of electrical energy, previously disconnect the pin from the network.

3.6

INDICATIONS

INFORMATION DEVICES

In the pump: Oil level, oil filling tap, pressure relief valve, additional gauge port.

In the cylinder: A gauge in order to know the operating pressure anytime.

The press, the cylinder and the pump have their corresponding serial numbers marked on them. In addition to it, you can find a sticker label showing the commercial

reference, capacity, working pressure, name and address of the manufacturer.

4. TRANSPORT AND INSTALLATION.

The machine is delivered properly packed in a wooden ballet. For it’s handling, it is recommended to use a forklift truck or a crane. In the last case, it is necessary to

make the slings trespass the arc of the frame. When doing this operation, you should be cautious and prevent the flexible hoses and couplings from any damage.

HYDRAULIC CONNECTION

Unscrew the rapid coupler site in the cylinder, and connect the hose, screwing the rapid coupler to the limit with the hand.

SUBSTITUTION OF THE TRANSPORT PLUG

Replace the plug of the transport located in the cover of the tank by the pressurized plug given with the press. (Plastic stock marked in the handle of the distributing

valve).

INSTALLING THE GAUGE

1-Replace the threaded tap in the top of the cylinder by the gauge, which is supplied separately.

2-Tighten the gauge cone to the gauge adaptor seat by using a flan wrench size 22.

3-Hold the gauge screen by hand during threading process and after reaching a comfortable reading position set the gauge screen free so that it turns the last quarter

solidarily with the thread.

4- The power pack is also provided with a gauge adaptor, with thread 3/8” BSP.

ELECTRIC CONNECTION

1-

Connect the binding post to the network

2-

See the voltage, it must be 380 V

3-

Assure that the valve is in neutral position; it is to say “C” position.

4-

Put the general selector in (1) position. The motor starts.

5-

Check that the motor goes in the sense labelled with and arrow in the motor. In opposite case, change the position of two cables between themselves in the

terminal and try again. This operation must be done with the equipment disconnected.

6-

Connect again the equipment and check the function.

CHECKING THE RIGHT OPERATION OF ALL DEVICES AND MECHANISM

1.

Select the working maximum pressure.

2.

Start the motor.

3.

Check that the cylinder’s piston advance.

4.

Check that the cylinder’s piston returns pushing by an internal spring. In both cases act over the valve as explained in previous point.

5.

With no material in the press, repeat the movement of advance, reaching the end of the stroke of the cylinder. In this moment the pressure will go

increasing, so the gauge will read the pressure. This pressure will go increasing until reach the maximum pressure of the installation, previously

chosen. The cylinder maintains the reached pressure and the gauge the pressure reading.

6.

Check that there are not oil leaks.

7.

Act over the valve and return the piston. It returns by the internal spring. The return could be slower in the end of the return stroke.

8.

Put the material to be treated in the press.

9.

Once the operation is finished, push the red button to stop the motor.

10.

Put the general selector in (0) position,

The machine is stable enough to operate without fixing, but if is placed in an area commonly operated by mobile machinery (cranes,

lifting equipment…) it is strongly recommended to fix it to the desired place by drilling the supporting plates.