5

MANUAL BACK UP

This a toggle switch located below the control panel, behind the louvered

access door. In the event of a computer failure, this switch takes control of

the oven away from the computer and directs the temperature control to a

mechanical thermostat located next to the switch.

BACK-UP THERMOSTAT

Activated when the Manual Back-up switch is set to On. This thermostat

controls the oven temperature in the event of a computer failure.

BACK-UP STEAM

Installed on Steam Injected models only and activated when in the Manual

Back-up mode. This switch allows the operator to manually inject steam

into the oven cavity.

STATUS SCREEN

The Status Screen informs the operator of the

ovens current operating condition.

It can be used, during the baking cycle, as a

countdown timer, shelf in use, or internal oven

temperature display (See separate Programming

Instructions).

The Status Screen informs the operator when the

oven is ready to bake or if the oven temperature

is above or below the programmed temperature.

Below is a list of display terms and their

definitions.

"EntEr"

The oven is energized and ready for an operator command.

"PrEHt"

Stands for PREHEAT. A product button has been selected and the oven is

heating to the programmed temperature.

"COOL"

A product change has been made and the oven's internal temperature is

below the new product.

"HOt"

A product change has been made and the oven's internal temperature is

above the programmed temperature of the new product.

"SHELF"

A product selection has been made after the oven has preheated and the

computer is asking which shelf the product is placed on.

"HELP"

There is a fault in the control system. The computer will not operate until

service is performed.

"COnt"

Stands for Continuos. When this is displayed, the oven has been

programmed without a cooking time being entered. The oven will operate

continuously at the programmed temperature.

"ErrOr"

An entry has been made during programming which is outside the

parameters of the computer.

TYPICAL OPERATION

Once the Product Buttons are programmed, all of

the oven's operation is controlled by the

computer.

To select a product, simply press the

programmed Product Button which is labeled for

the product you wish to cook.

Once a Product Button is selected, the oven will

preheat to the preprogrammed temperature.

The control will not allow the operator to select

a shelf until the oven has reached its

programmed temperature.

Once the programmed temperature is reached the

Status Screen will display "

REAdY"

and the

beeper will sound briefly.

Only the Product Buttons which are programmed

at the same temperature as the oven will now be

activated (the button lamp will flash).

Содержание GCCO-C

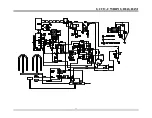

Страница 16: ...13 GCCO C WIRING DIAGRAM...