11

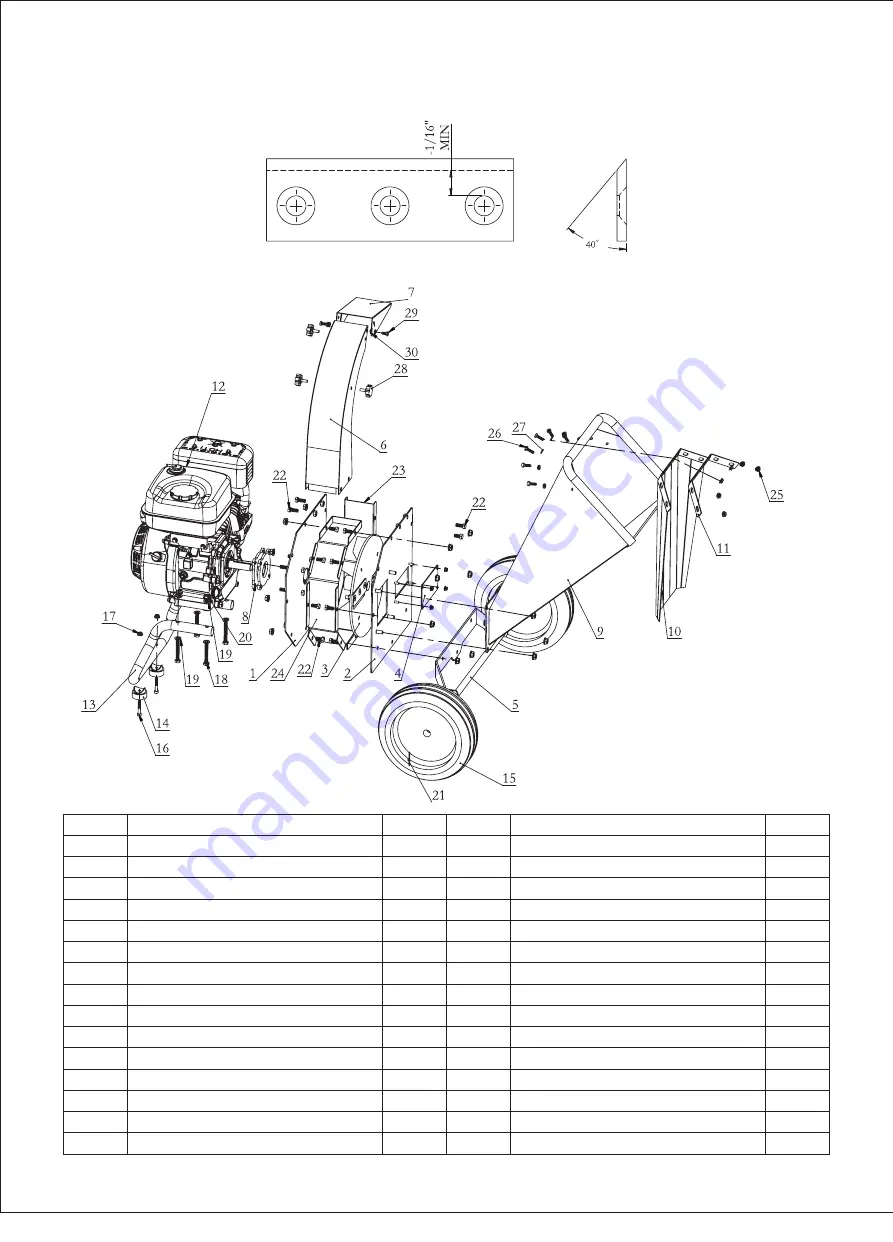

Chipping Knives Sharpening and Replacement

1. The chipping knives should be sharpened or replaced when tree limbs require extra force to feed into the chipper cone.

2. The chipping knives may be sharpened at a 39 degree angle until the distance between the edge of the blade

bevel and the mounting hole is less than 1/16” (1.6mm). See Figure 6.

Parts Breakdown

Figure 6

Part No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Description

Back of side plate

Front of side plate

Knife assembly

Window plate

Wheel bracket

Discharge chute

Discharge chute guide

Bearing Seat

In-feed bin

Hopper guard

Guard plate

Engine

Engine support

Stand pad

Wheel

Q’ty

1

1

1

1

1

1

1

2

1

1

1

1

1

2

2

Part No.

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Description

Screw M6x40

Locking nuts M6

Flange Bolt M8*60

Flat washer

Flange Locking Nut M8

Split pin

Bolt M8*16

Cowl panel

Cowl panel

Locking nut M6

Bolt M6x20

Flat washer φ6

Star handle

Bolt M6*12

Elastic washer

Q’ty

2

2

8

8

20

2

17

1

1

8

6

8

3

2

2

Size

:

210x285mm

157G

铜版纸

REV 08/16/18