28

Section 3: Operating Instructions

RCR3596, RCRM3596, RCR3510 & RCRM3510 Rotary Cutters 312-517M

8/15/12

Table of Contents

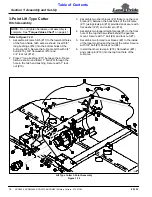

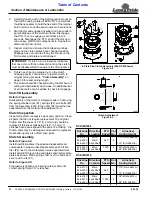

Turning Angles for Pull-Type Cutters

Refer to Figure 3-1 and 2-3:

Avoid tractor-to-cutter turning angles exceeding 35

degrees if the main driveline is a standard conventional

drive shaft. The turning angle may be increased to 80

degrees if equipped with a constant velocity driveline

shaft. These extreme angles are intended for intermittent

usage only and not prolonged usage. Plan your field

cutting to minimize the number of turns as well as

extreme angles where turns are necessary.

Conventional U-Joint Driveline

Figure 3-1

CV Driveline

Figure 3-2

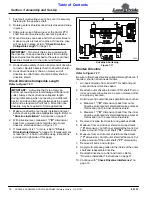

Crossing Steep Ditches & Banks

Refer to Figure 3-3:

!

WARNING

Damage to the tractor’s PTO components and/or driveline

components can cause driveline to come loose and cause

bodily injury to the operator and others.

Crossing Steep Ditches and Banks

Figure 3-3

11934

20795

IMPORTANT: Always cross steep ditches and banks

at a diagonal. Never cross straight across and never

back into a steep ditch or bank.

Ditch / Bank

Wrong

Right

Ditch / Bank

Cutting over ditches and backing up hills can tilt the

cutter’s back side up excessively resulting in “Bottoming

Out” the driveline. Bottoming out is when the driveline

shaft has shorten to the point it is pressing against the

gearbox and tractor PTO shafts. Once a driveline has

bottomed out, it can not be shorten anymore without

causing serious damage to the tractor PTO components,

cutter gearbox and driveline.

Do not operate a pull-type cutter at an angle exceeding

25 degrees up or down or at any angle that will force the

driveline to bind and/or hit the tractor drawbar.

Unhook 3-Point and Semi-Mount

!

WARNING

Always disengage PTO, engage parking brake, shut tractor

engine off, remove switch key, and wait for blades to come to

a complete stop before dismounting tractor.

1.

See “Long Term Storage” on page 34 if cutter is not

going to be used for a long time.

2.

Park on a level solid surface and lower deck to

ground level or onto support blocks.

3.

Engage tractor park brake, shut tractor engine off,

and remove switch key. Stay on tractor until blades

have come to a complete stop.

4.

Disconnect driveline and safety chain from tractor.

5.

Unhook 3-Point hitch from tractor and drive tractor

forward several feet.

6.

Reinstall hitch pins, linch pins, and hair pin cotters in

cutter hitch for safe keeping.

7.

Collapse driveline by pushing tractor end of driveline

towards the cutter. Support driveline off the ground.

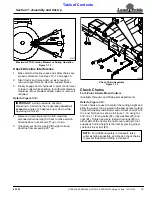

Unhook Pull-Type

Refer to Figure 1-8 on page 14:

!

WARNING

Always disengage PTO, engage parking brake, shut tractor

engine off, remove switch key, and wait for blades to come to

a complete stop before dismounting tractor.

1.

See “Long Term Storage” on page 34 if cutter is not

going to be used for a long time.

2.

Park cutter on a level solid hard surface. Place tractor

gear selector in park and set park brake.

3.

Fully raise deck up to transport position. Add stroke

control spacers to the cylinder rod to prevent the

cylinder from retracting. See “Hydraulic cylinder

Instructions” on page 22.

4.

Remove parking jack (#1) from cutter deck and

secure to cutter tongue by fully inserting jack locking

pin (#2) through parking jack and mounting bracket.

IMPORTANT: Always place parking jack on a firm

surface or place a board under the parking jack for