PAGE 3

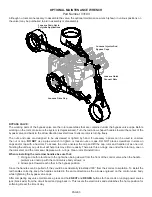

TO INSTALL 5/8” POLY TUBE DRAIN LINE:

The poly tube insert is shipped attached to the drain line elbow’s locking clip.

Press the insert into the drain line (5/8” poly tube not included). Loosen nut of the drain line elbow. Press 5/8” poly tube with

insert into the drain line elbow until it seats on the back of the fitting. Tighten nut.

It is simplest to run the drain line into a sump pump pit or washing machine drain if possible. If this is not practical, a fitting

with a trap must be installed in a sewer line. Place the trap as close to the vent as possible to prevent siphoning of the trap

when large amounts of waste water go through the sewer line. DO NOT pipe the drain line solidly into the waste line, as this

is prohibited by most plumbing codes. The drain line should enter the trap from above so the water will not back up in the

drain line if sewer should become plugged up and the trap overflow. The trap should have a short pipe extending from it to

prevent splashing when water runs into the trap from drain line.

BRINE LINE CONNECTIONS:

3/8” poly tube is shipped within the instruction/warranty card packet affixed to the control

valve. One poly tube insert is shipped on the brine line elbow’s locking clip, the second is taped to the cap of the brine well.

Remove the locking clip by pulling straight out. Remove the white poly tube insert from the locking clip, and replace the

locking clip on the brine line elbow of the control valve.

Press the poly tube insert into the provided 3/8” poly tube. Press the poly tube and insert into the nut until it is fully seated

into the fitting. Do not use pipe dope or any other sealant on threads. Teflon tape is not needed on the threads. Tighten nut

securely to create a pressure tight connection. Pliers or crescent wrench may be used. The nut, gripper and retainer sleeve

is a three piece assembly that can come apart if removed from the elbow body. Parts must be reassembled exactly as

shown to function properly. If the nut is completely removed from the body, slip the nut, plastic gripper and retainer sleeve

on to the tube then tighten on to the fitting.

Click to buy NOW!

PD

F-

XC

H

A

NG

E

ww

w

.d

oc

u-

tr

ac

k.

co

m

Click to buy NOW!

PD

F-

XC

H

A

NG

E

ww

w

.d

oc

u-

tr

ac

k.

co

m

Install the second poly tube insert into the end of the 3/8” poly tube and repeat instructions above to install into the brine

tank’s brine line fitting.

BRINE TANK OVERFLOW PRECAUTION:

Attach a 1/2” poly tube (not provided) to the barbed fitting on the outside of the

tank. This poly tube should be piped to drain to allow brine to discharge to drain in the event of an overflow condition.

PROGRAMMING THE CONTROL VALVE:

Note: A quick-reference card is stored inside the front cover of the control valve.

To access this card, slightly pull tabs on side of cover outward and pull cover forward. Plug the electrical cord into a 115

Volt receptacle. DO NOT plug into an outlet controlled by a wall switch or pull chain that could inadvertently be turned off.

Wait a couple of seconds for control valve to “home” itself. Panel should display “TIME” and the time of day will be flashing.

SET TIME OF DAY

STEP 1: Press

SET CLOCK

.

STEP 2: Set current hour of the day by pressing ▲

or ▼ buttons. AM/ PM toggles after 12.

STEP 3: Press

NEXT

. Set current minutes by

pressing ▲ or ▼ buttons.

STEP 4: Press

NEXT

to exit

SET CLOCK

.

Click to buy NOW!

PD

F-XCHANGE

w

ww

.docu-track.c

om

Click to buy NOW!

PD

F-XCHANGE

w

ww

.docu-track.c

om

FIGURE 1

TO INSTALL 5/8” POLY TUBE DRAIN LINE:

The poly tube insert is shipped attached to the drain line elbow’s locking

clip. Press the insert into the drain line (5/8” poly tube not included). Loosen nut of the drain line elbow. Press 5/8” poly tube

with insert into the drain line elbow until it seats on the back of the fitting. Tighten nut.

It is simplest to run the drain line into a sump pump pit or washing machine drain if possible. If this is not practical, a fitting with

a trap must be installed in a sewer line. Place the trap as close to the vent as possible to prevent siphoning of the trap when

large amounts of waste water go through the sewer line. DO NOT pipe the drain line solidly into the waste line, as this is

prohibited by most plumbing codes. The drain line should enter the trap from above so the water will not back up in the drain

line if sewer should become plugged up and the trap overflow. The trap should have a short pipe extending from it to prevent

splashing when water runs into the trap from drain line.

BRINE LINE CONNECTIONS:

3/8” poly tube is shipped within the instruction/warranty card packet affixed to the control

valve. The poly tube inserts are shipped on the brine line elbow’s locking clip. Remove the locking clip by pulling straight out.

Remove the white poly tube insert from the locking clip, and replace the locking clip on the brine line elbow of the control valve.

Press the poly tube insert into the provided 3/8” poly tube. Press the poly tube and insert into the nut until it is fully seated into

the fitting. Do not use pipe dope or any other sealant on threads. Teflon tape is not needed on the threads. Tighten nut

securely to create a pressure tight connection. Pliers or crescent wrench may be used. The nut, gripper and retainer sleeve is

a three piece assembly that can come apart if removed from the elbow body. Parts must be reassembled exactly as shown to

function properly. If the nut is completely removed from the body, slip the nut, plastic gripper and retainer sleeve on to the tube

then tighten on to the fitting.

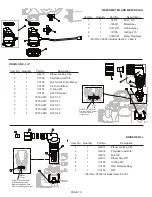

SET TIME OF DAY

STEP 1: Press

SET CLOCK

.

STEP 2: Set current hour of the day by pressing ▲

or ▼ buttons. AM/ PM toggles after 12.

STEP 3: Press

NEXT

. Set current minutes by

pressing ▲ or ▼ buttons.

STEP 4: Press

NEXT

to exit

SET CLOCK

.

SET

CLOCK

NEXT

▲

▼

REGEN

STEP 2

6:

35

PM

SET TIME

STEP 1

STEP 3

6

:35

PM

SET TIME

SET

CLOCK

NEXT

▲

▼

REGEN

SET

CLOCK

NEXT

▲

▼

REGEN

Install poly tube insert into the end of the 3/8” poly tube and repeat instructions above to install into the brine tank’s brine line

fitting.

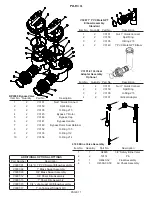

BRINE TANK OVERFLOW PRECAUTION:

Attach a 1/2” poly tube (not provided) to the barbed fitting on the outside of

the tank. This poly tube should be piped to drain to allow brine to discharge to drain in the event of an overflow condition.

PROGRAMMING THE CONTROL VALVE:

Note: A uickreference card is stored inside the front cover of the control

valve. To access this card, slightly pull tabs on side of cover outward and pull cover forward. Plug the electrical cord into a 115

Volt receptacle. DO NOT plug into an outlet controlled by a wall switch or pull chain that could inadvertently be turned off. Wait

a couple of seconds for control valve to “home” itself. Panel should display

“TIME”

and the time of day will be flashing.

FIGURE 1

Page 3

3/8”

POLY TUBE