10

5

OPERATING PRINCIPLES AND SETTING THE PARAMETERS

After being switched on and running the self-test, the machine will start from its initial

settings:

Standard mode, 7 ms impulse length/welding time, and a low power setting.

The initial settings for mode, welding time and power, correspond to the blue LEDs in the

display. The display also has blue LEDs to mark the entire parameter range.

Important !

At the outset, until a basic proficiency is reached, we recommend to only change the

parameter welding power, leaving the welding time constant. After a short time, when

you have become more confident with the technique and have gained more experience,

then you can naturally also change the welding time to suit your needs.

The machine automatically saves the last three sets of welding parameters that

have been used.

By pressing in the rotary knob “Impulse length / welding time” (3), these previous settings

can be recalled one after another.

Even when the machine is switched on, or after accidentally changing the parameters,

the settings that were last used are there to be recalled again.

Please note !

Please remember that only when the gas flow rate has been correctly set up and

adjusted, can good welding results be achieved.

To adjust the gas flow to the correct amount, press in and hold the rotary knob – welding

power (4). (The gas valve in the machine will now be open and the gas will flow freely).

Without letting go of the rotary knob – welding power (4), adjust the Flowmeter regulator

to the correct flow rate ca.

2

litres per minute.

5-1

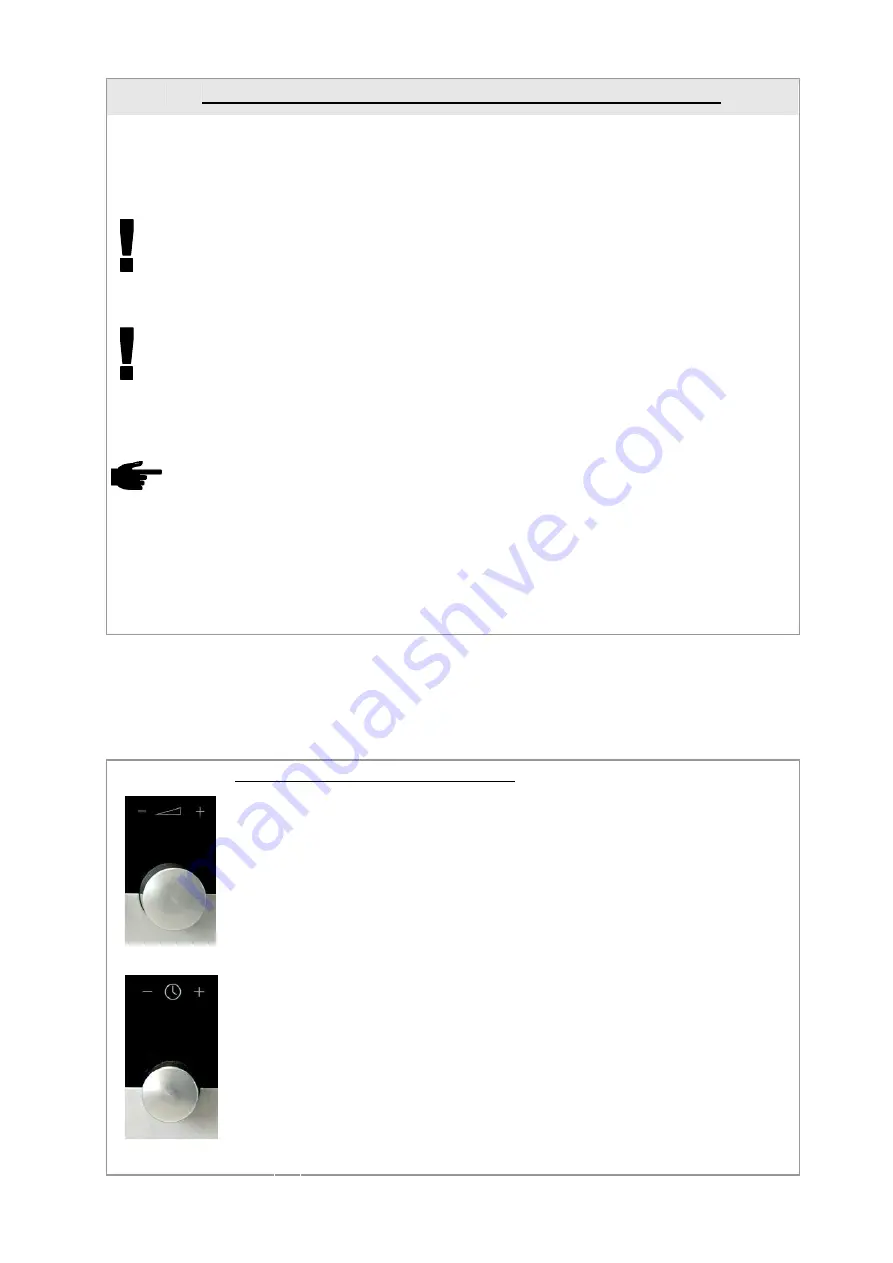

SETTING THE WELDING PARAMETERS

Power:

The welding power (potency of the welding energy), can be set by

adjusting the rotary knob – welding power (4)

The size and intensity of the welding spot can thus be governed.

Welding time:

Using the rotary knob – Impulse length / welding time (3), the user can

regulate for how many milliseconds the welding energy impacts upon the

work piece.

Depending on the angle at which the electrode is held in relation to the

work piece, the penetration depth and direction of flow (of molten metals),

can be influenced.

The penetration depth is at its greatest when the electrode is held

vertically to the work piece.