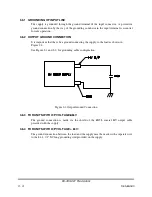

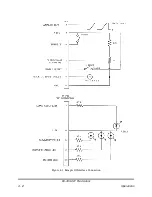

The Series 500A/102A/152A/202A is easily controlled through the remote connector on

the input panel of the unit. Only the ENABLE/RESET, V PROGRAM and GND signals

are required for operation. The remaining signals are provided for status monitoring and

fault diagnosis. A schematic diagram showing the suggested interface circuit is shown in

Figure 4-1. This table is for a standard configuration.

Indicates a shorted O/P or a very large load capacitor.

OUTPUT

LOAD FAULT

2

Open collector. Indicates an output overvoltage.

Temperature fault or low input voltage condition.

OUTPUT

SUMMARY

FAULT LED

3, 6

Open collector. Indicates that the power supply is

reaching end-of-charge, i.e. the V PROGRAM set point.

OUTPUT

EOC LED

13

Open collector. Indicates that the power supply is

receiving an INHIBIT signal.

OUTPUT

INHIBIT LED

15

Control circuit return. Also chassis/earth ground

OUTPUT

GND

14

15V regulated. Can be used for user programming

applications 20mA max.

OUTPUT

+15V

9, 11

A +10 to 15V with respect to ground, disables the unit.

Open or ground allows operation. This input can be

used to disable charging during HV switch recovery.

INPUT

INHIBIT

10

0-10V analog of output charging voltage waveform.

OUTPUT

V

ANALOG

8

A 0-10V signal (with respect to ground) proportional to

the peak of the output charging voltage. Can be used to

drive a meter displaying peak output voltage.

OUTPUT

V

PEAK

7

A 0-10V signal with respect to ground at this pin

programs the output voltage proportionally from zero to

rated output.

INPUT

V PROGRAM

5

A high signal (+10 to 15V) with respect to ground

(pin 14) will enable the power supply. Latching faults

can be cleared by cycling this switch. Ground or open

disables the supply.

INPUT

ENABLE/RESET

1

DESCRIPTION

I/O

SIGNAL NAME

PIN

Table 4.1 Control Interface Connection For Standard 500A/102A/152A/202A Series

83-493-001 Revision G

4 - 1

Operations