Lake Shore Model 642 Electromagnet Power Supply User’s Manual

2-2

Magnet System Design

2.2 MAGNET

CONSTRUCTION

The magnet consists of two water-cooled coils surrounding adjustable iron poles, which are fitted into an iron frame.

The frame supports the poles and coils, and improves the magnet’s efficiency. The iron poles are fitted with adjusting

mechanisms so that the air gap width can be set. Lock mechanisms are provided to hold the poles in place after

adjustment is made. The poles faces have pole caps attached, which provide the desired magnetic focus. The size and

shape of the pole caps are chosen according to the size of sample being tested and the magnetic field requirement.

2.3

CONNECTING THE MAGNET

Connecting the magnet to the power supply requires three separate circuits: the cooling water hoses, the main high

current power lines, and the safety switches which may include any combination of temperature and flow switches.

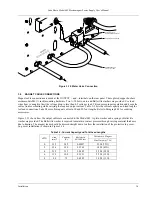

These connections are shown below.

2.3.1

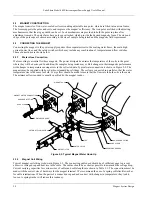

Water Hose Connection

Water-cooling is essential for these magnets. The power dissipated can raise the temperature of the coils to the point

where they will be destroyed. In addition, the samples being tested may exhibit changes in their magnetic performance

with changes in temperature causing errors in the collected data. Typical water connection is shown in Figure 2-2. The

magnets may be supplied with hose barbs or standard hose fittings. The coils are connected in parallel so that the water

temperature rise is the same for both. Every effort should be made to insure that the flow rate in both coils is the same.

The minimum flow required is usually specified by the magnet vendor.

HOSE CLAMP

HOSE BARB FITTING

MAGNET WATER CONNECTION

REENFORCED HOSE

WATER FILTER

WATER VALVE

TEE

OPTIONAL FLOW SWITCH

MAGNET COIL

HOSE BARB FITTING

HOSE CLAMP

REENFORCED HOSE

Figure 2-2. Typical Magnet Water Hook-Up

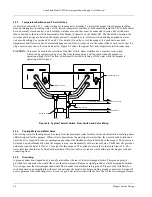

2.3.2 Magnet

Coil

Wiring

Typical magnet coil wiring is shown in Figure 2-3. The connecting cable used should be of sufficient gage to prevent

excessive voltage drop and heat rise in the cable. The cables should be as short as possible to minimize the voltage drop.

Current carrying capacities for various sizes of cables and cable lengths are shown in Table 3-3. The connections must be

made with the correct size of hardware for the magnet terminal. We recommend the use of a spring or Belleville washer

for cable terminations. When the parts of a connection expand and contract with changes in temperature, they tend to

loosen. A spring washer will reduce this tendency.