49

Rust.

The bandsaw is made from steel and cast iron. All non-painted surfaces will rust if not

protected. It is recommended that the table be protected by coating with wax if the machine is

not in constant use. All moving non-painted surfaces (guides, rack and pinion, etc.) should be

lubricated/protected with a Teflon-based lubricant.

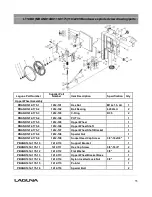

Blade guide rack and pinion.

The top guide when moved vertically tracks the blade and comes factory-set. Adjustment

is provided should that mechanism become misaligned. This is a tricky operation and

should only be attempted if an extreme error has

occurred.

Back guide forward/back adjustment.

1.

Four clamping bolts and two Allen jacking

screws are provided.

2.

Slightly loosen the two clamping bolts A and

tighten the bottom Allen screw B will bring the

guide forward.

3.

Slightly loosen the two clamping bolts C and

tighten the top Allen screw D will bring the guide

back.

4.

Make only very small adjustments. Tighten the

clamping bolts prior to checking the guide vertical

movement.

Note:

The machine comes factory-set, and no adjustment should be required.

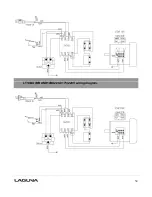

Adjusting the break.

Back break adjustor

Front break adjustor

Flywheel not shown for clarity

The back break adjustor moves clockwise to remove slack in the break pad.

The front break adjustor is rotated clockwise with an allen key to remove slack in the break

pad.

Clamp bolts C Allen jacking screw D

Clamping bolts A Jack bolt B