Product Service 1-800-522-7658

38

Original instructions

A

PPENDIX

A

P

ROTECTOR

P

ASS

-T

HROUGH

C

OMPONENTS

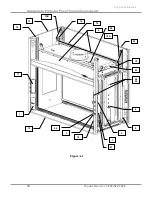

Illustration A-1 indicate the location of the following service parts:

Item

Quantity

Part No.

Description

1A

1

9823700

Valve, Labconco (Water) 1/4" Compression Fitting

1B

1

9823701

Valve, Labconco (Water) 3/8" Compression Fitting

1C

1

9817000

Valve, Labconco 1/4" Compression Fitting (AIR, GAS, VAC, NIT, etc.)

1D

1

9817001

Valve, Labconco 3/8" Compression Fitting (AIR, GAS, VAC, NIT, etc.)

1E

1

9823702

Valve, Labconco Deionized 1/4" Compression Fitting

1F

1

9823703

Valve, Labconco Deionized 3/8" Compression Fitting

1G

1

9818000

Nut, Valve Mounting (Labconco)

2A

1

9826800

WaterSaver Valve/Gooseneck – GRN

2B

1

9826801

WaterSaver Valve/Connector (VAC) – YEL

2C

1

9826802

WaterSaver Valve/Connector (AIR) – ORG

2D

1

9826803

WaterSaver Valve/Connector (GAS) – BLU

2E

1

9826805

WaterSaver Valve/Connector (HOT WATER) – RED

2F

1

9826806

WaterSaver Valve/Connector (CW) – GRN

2G

1

9826807

WaterSaver Valve/Connector (STEAM) – BLK

2H

1

9826808

WaterSaver Valve/Connector (NITROGEN) – BRN

2I

1

9826809

WaterSaver Valve/Connector (OXYGEN) – LIGHT GREEN

2J

1

9826810

Swivel Gooseneck only – GRN

2K

1

9826812

Swivel Gooseneck only – WHITE

3

1

9818700 thru 08

Knobs (GRAY, GRN, BLU, ORG, YEL, RED, WHT, BLK, BRN)

4A

1

9818800

Hose Barb, GRAY (NEUTRAL OR ARGON) – NOT SHOWN

4B

1

9818801

Hose Barb, GREEN (COLD WATER) – NOT SHOWN

4C

1

9818802

Hose Barb, BLUE (GAS) – NOT SHOWN

4D

1

9818803

Hose Barb, ORANGE (AIR) – NOT SHOWN

4E

1

9818804

Hose Barb, YELLOW (VACUUM) – NOT SHOWN

4F

1

9818805

Hose Barb, RED (HOT WATER) – NOT SHOWN

4G

1

9818806

Hose Barb, WHITE (DEIONIZED WATER) – NOT SHOWN

4H

1

9818807

Hose Barb, BLACK (NEUTRAL OR STEAM) – NOT SHOWN

4I

1

9818808

Hose Barb, BROWN (NITROGEN) – NOT SHOWN

4J

1

9819000

Nut, Hose Barb – NOT SHOWN

5

1

9825500

Label, Knob (contains all the labels)

6

1

9818900

Lens, Knob

7A

1

9947100, 01

115V Duplex Receptacle (GRAY) Right (00), Left (01) w/ wires

7B

1

9818200

Cover Plate 115V Duplex

7C

1

9947103, 04

115V GFCI Duplex Receptacle (GRAY) Right (03), Left (04) w/ wires

7D

1

9818100

Cover Plate, 115V GFCI

7E

1

9818300

Cover Plate, Blank

Protector Pass-Through Replacement Parts