Rigging procedures

39

X8 rigging manual (EN) version 1.0

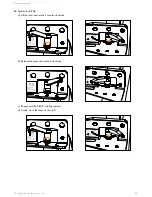

5.

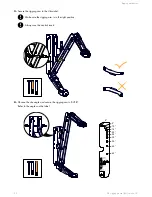

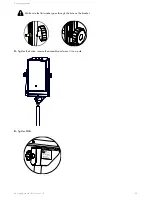

Position the shackle or CLAMP250 to select the site angle.

— Rear extension on horizontal enclosure

+28°

+16°

+3°

+11°

+24°

— Front extension on horizontal enclosure

+1°

+14°

+27°

+37°

+47°

— Rear extension on vertical enclosure

+5°

-5°

-14°

-23°

-31°

— Front extension on vertical enclosure

+22°

+13°

+3°

-6°

-15°

Содержание X8

Страница 1: ...X8 rigging manual 1 0 EN...

Страница 4: ...4 EMBi specifications 56...

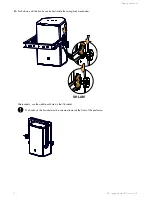

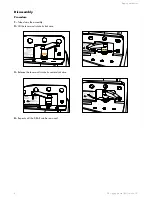

Страница 21: ...Rigging procedures 21 X8 rigging manual EN version 1 0 6 Tighten the knobs Make sure the enclosure is steady...

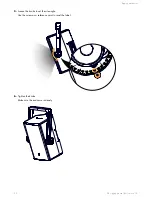

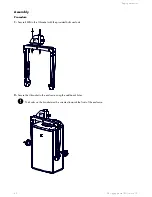

Страница 40: ...Rigging procedures X8 rigging manual EN version 1 0 40 6 Lift the assembly...

Страница 47: ...Forbidden configurations 47 X8 rigging manual EN version 1 0 Forbidden configurations Forbidden Authorized...

Страница 57: ......