3M0

1-3-1

1-3 Maintenance Mode

1-3-1 Maintenance mode

The machine is equipped with a maintenance function which can be used to maintain and service the machine.

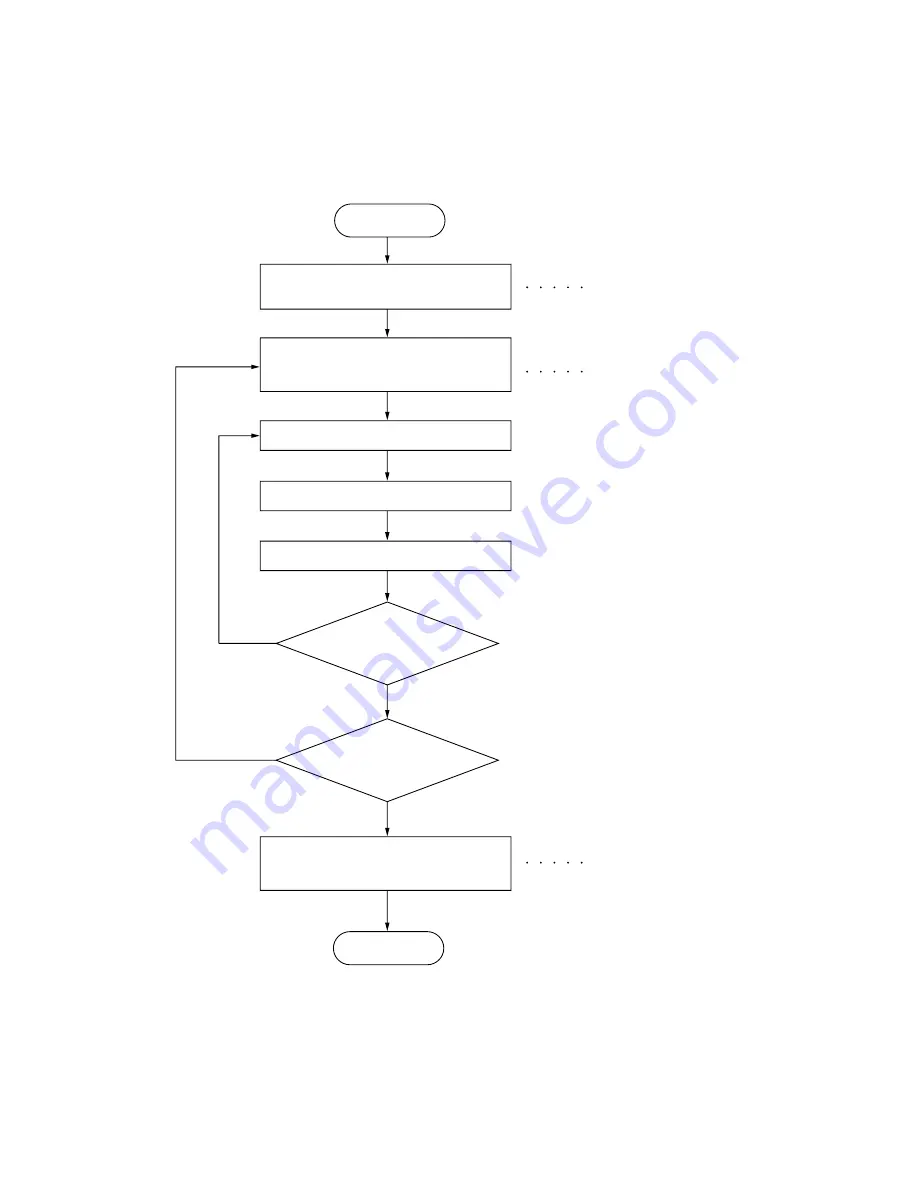

(1) Executing a maintenance item

Enter 10871087 using

the numeric keys.

Enter 001 using the cursor

up/down keys or numeric keys

and press the start key.

Enter the maintenance item

number using the cursor up/down keys

or numeric keys.

The selected maintenance item is run.

Press the stop/clear key.

Press the start key.

Start

End

Maintenance mode is entered.

The maintenance item is

selected.

Maintenance mode is exited.

Repeat the same

maintenance item?

Run another maintenance

item?

No

No

Yes

Yes

Содержание PF-660

Страница 1: ...SERVICE MANUAL Published in December 2008 843M0110 3M0SM060 First Edition PF 660 B...

Страница 3: ...Revision history Revision Date Replaced pages Remarks...

Страница 4: ...This page is intentionally left blank...

Страница 10: ...This page is intentionally left blank...

Страница 12: ...3M0 This page is intentionally left blank...

Страница 15: ...3M0 1 1 3 1 1 3 Cross section view Figure 1 1 2 Paper path Paper feed section Paper lifter lift section...

Страница 16: ...3M0 1 1 4 This page is intentionally left blank...

Страница 20: ...3M0 1 2 4 This page is intentionally left blank...

Страница 44: ...3M0 2 1 4 This page is intentionally left blank...

Страница 52: ...3M0 2 4 2 This page is intentionally left blank...

Страница 53: ......

Страница 54: ......