EN

PL

17

RU

DE

OPERATING INSTRUCTIONS

During operation, the pressure in the tank will decrease. Restore the tank pressure by pumping. During pumping

the spray liquid (suspension) is mixed in the tank, and its fractionation is thus prevented.

The ball valve (fig. 8a/pos. 1) mounted in the handle (fig. 8a/pos. 2) has several functions. It acts as a valve,

i.e. opens and closes the flow of the spray liquid. It acts as flow regulator. It can also ensure the steady flow of

spray liquid - continuous spraying

After finishing work you must depressurise the tank - see PREPARATION FOR WORK.

The device may be carried by the shoulder strap or by the piston rod handle, which must be locked in the cylin-

der brackets for this purpose. In both cases, the pump must be tightly screwed into the head.

STORAGE AND MAINTENANCE

Each time after work wash the applicator thoroughly with clean water.

Depressurise the tank (fig. 1/pos. 8) by pulling the safety valve pin (fig. 4a/pos. 1). Remove the pump (fig. 1/

pos. 5), pour clean water into the tank (fig. 1/pos. 8, approx. 0.25 of the tank capacity), screw in the pump

(fig. 1/pos. 5) until sealed and pump the tank. Conduct some spraying onto the previously sprayed surfaces

in order to rinse the device’s spraying system. After you finish, depressurise the tank (fig. 1/pos. 8) with the

safety valve (fig. 4a/pos. 1) and remove the head (fig. 1/pos. 5). Remove the remaining water from the tank.

The applicator should be stored

WITHOUT PRESSURE

in the temperature b5

°

C and +35

°

C,

in a shaded place, away from heaters and out of reach of children. It is recommended to remove the pumps

(fig. 1/pos. 5) from the head (fig. 1/pos. 2).

The nozzle (fig. 12/pos. 3) located at the lance tip (fig. 1/pos. 1) must be cleaned periodically and before

any prolonged downtime.

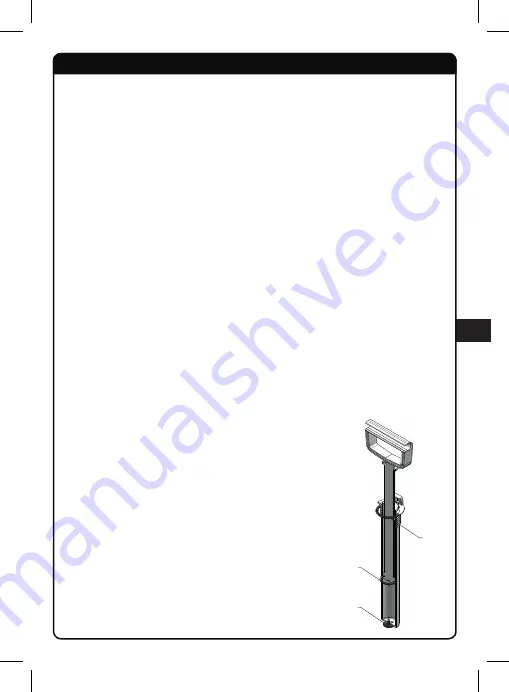

If the sprayer will not be used for a long period of time, maintenance work

must be performed. Remove any residue of the spraying agent from the

sprayer, rinse the sprayer with clean water and then lubricate the seals with

silicone oil (included).

In addition, periodically lubricate the moving parts and seals of the

sprayer with silicone oil.

This applies especially to the seals marked with

arrows in the figure below.

Fig.9

2

1

3