Designation

Article number

Quantity

Optigear ALR 320

(

>>>

iliary and oper-

ating materials

used"

Page 336

)

Initial fill-

ing quan-

tity: 2.49 l

Tightening torques

The tightening torques can be found under: (

>>>

)

These are valid for screws and nuts where no other specifications are giv-

en.

Screws of strength class 10.9 and higher as well as screws with test cer-

tification may only be tightened once with the rated tightening torque.

When the screws are first slackened they must be replaced with new

ones.

Precondition

• The robot is in a position in which the oil filler hole and oil drain hole

on the gear unit of axis 2 are accessible.

• The gear unit is at operating temperature.

Work safety

CAUTION

High oil and surface temperatures after the robot has stopped op-

erating

If the oil change is carried out immediately after the robot has stopped

operating, the oil temperature and the surface temperature are liable to

be high. Touching them may result in burns.

• Wear protective gloves.

WARNING

Danger to life and limb due to unintended robot motions

Unintended robot motions may result in death, severe injuries and dam-

age to property.

• Secure the robot by pressing the EMERGENCY STOP device.

• Warn all persons concerned before starting to put it back into opera-

tion.

8.4.1

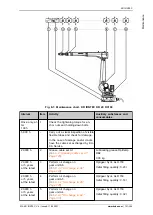

Draining the gear oil from A2

Procedure

1. Place a suitable receptacle under the rotating column

(

>>>

8.4.1 "Draining the gear oil from A2" Page 201

).

2. Remove the lower M18x1.5 magnetic screw plug on the rotating col-

umn.

It is easier to drain the oil if an M18x1.5 oil drain tube is screwed into

the oil drain hole.

3. Remove the upper M18x1.5 magnetic screw plug for venting and

catch the oil as it drains out.

4. Store or dispose of oil in accordance with the pertinent regulations.

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021

www.kuka.com

| 201/344

Maintenance

Содержание IONTEC KR 20 R3100

Страница 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Страница 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Страница 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Страница 300: ...Fig 9 58 Wiring diagram axis A2_KS A1 A3 KR IONTEC 300 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 301: ...Fig 9 59 Wiring diagram axis A3_KS A1 A3 KR IONTEC MA KR IONTEC V4 Issued 11 05 2021 www kuka com 301 344 Repair...

Страница 302: ...Fig 9 60 Wiring diagram axis A4_KS A1 A3 KR IONTEC 302 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 303: ...Fig 9 61 Wiring diagram axis A5_KS A1 A3 KR IONTEC MA KR IONTEC V4 Issued 11 05 2021 www kuka com 303 344 Repair...

Страница 304: ...Fig 9 62 Wiring diagram axis A6_KS A1 A3 KR IONTEC 304 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 318: ...KR IONTEC 318 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Decommissioning storage and disposal...

Страница 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...