ECM SYSTEM

WG1605-G-E3,WG1605-L-E3,WG1605-GL-E3, DM

1-48

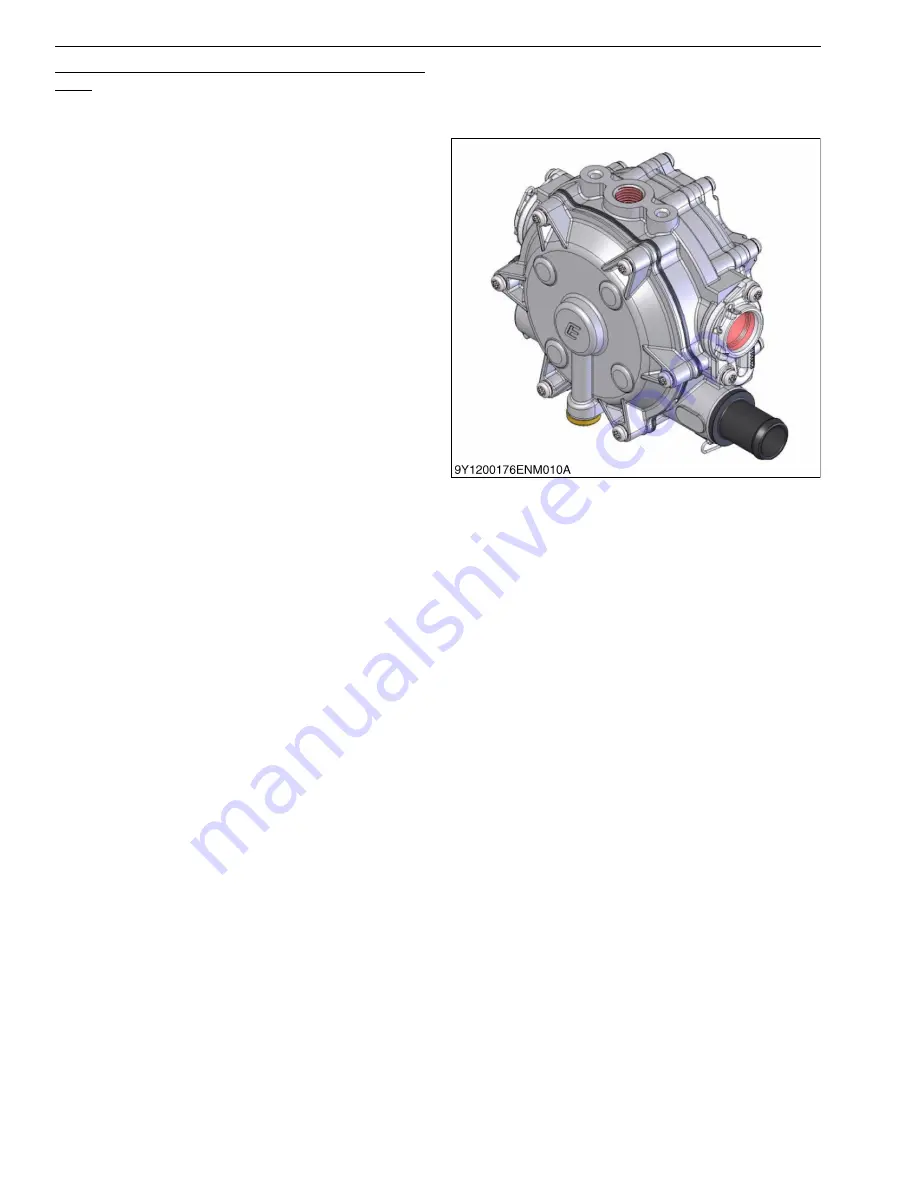

DUAL STAGE REGULATOR (DSR) (L, N, GL, LN,

GLN)

The DSR is a combination vaporizer, pressure

regulating device. The DSR is a two stage regulator that

is normally closed, when the engine is not running. When

the engine is cranking or running, a partial vacuum is

created in the fuel line, which connects the regulator to

the Direct Electronic Pressure Regulators (DEPR), and

mixer. This partial vacuum opens the second stage

regulator, permitting fuel to flow to the DEPR, and mixer.

LPG / natural gas fuel enters the primary port of the

DSR, and passes through the primary jet, and into the

primary/exchanger chamber. As the LPG / natural gas

passes through the heat exchanger, the fuel expands,

and creates pressure inside the chamber. The pressure

rises as the fuel expands, when the pressure rises above

10 kPa (0.11 kgf/cm

2

, 1.5 psi); sufficient pressure is

exerted on the primary diaphragm, to cause the

diaphragm plate to pivot, and press against the primary

valve pin, thus closing off the flow of fuel. This action

causes the flow of fuel, into the regulator to be regulated.

When the engine is cranking, sufficient vacuum will be

introduce into the secondary chamber, from the

EPR/mixer, drawing the secondary diaphragm down

onto the spring loaded lever, and opening the secondary

valve, allowing vaporized fuel, to pass to the mixer.

Increased vacuum, in the secondary chamber, increases

the downward action on the secondary lever, causing it

to open wider, allowing more fuel to flow to the mixer.

The DSR requires a connection to the engine

coolant, to prevent freezing in the regulator, during the

pressure reduction phase, within the regulator. Coolant

connections on the DSR are fitted with "Push In" fittings.

These fitting are designed with an o-ring seal, which

allows the fitting to be pushed into the water connection

on the DSR, and are then lock by spring locks, and

retained by screws.

The DSR is connected to the DEPR, by a low

pressure flexible hose. Like the other fuel hoses used in

the fuel system, the low pressure hose is designed with

a special inner core, and is usually wire reinforced, to

prevent collapse of the hose, during high demand fueling

operations. The low pressure hose should only be

replaced, with the recommended

Kubota

hose

replacement.

The packaging of the regulator, into the engine and

chassis, must be approved by Kubota, to insure

continued long term operation, of the fuel delivery and

emission control system. You should never relocate the

regulator, or any of the fuel system components, as

doing so, may cause excess build up of oil in the

regulator, improper coolant flow, or improper fuel

delivery.

In certain regions, fuel supplies may be made up of

much different chemicals and during the heating of the

fuel, in the heat exchange section of the regulator,

"heavy end" or petroleum oils, may accumulate over

time. To drain the DSR, remove the fuel outlet hose and

pour the oils out of the regulator. To determine the

frequency, for draining the regulators, refer to the

Recommended Maintenance Schedule.

The regulator utilized on USA emission certified

engines, are a critical part of the certified emissions

system, and does not require any periodic adjustment.

Figure 14:

Dual Stage Regulator (DSR)

KiSC issued 12, 2016 A

Содержание WG1605-E3

Страница 1: ...WG1605 E3 DIAGNOSIS MANUAL ECM SYSTEM KiSC issued 12 2016 A...

Страница 3: ...I INFORMATION KiSC issued 12 2016 A...

Страница 4: ...CONTENTS 1 SAFETY FIRST I 1 INFORMATION KiSC issued 12 2016 A...

Страница 8: ...1 ECM SYSTEM KiSC issued 12 2016 A...

Страница 10: ...23 Spark Coil Primary DTC 2300 2301 2303 2304 2306 2307 2309 2310 1 228 KiSC issued 12 2016 A...