0,4 - 0,8

mm

3

4

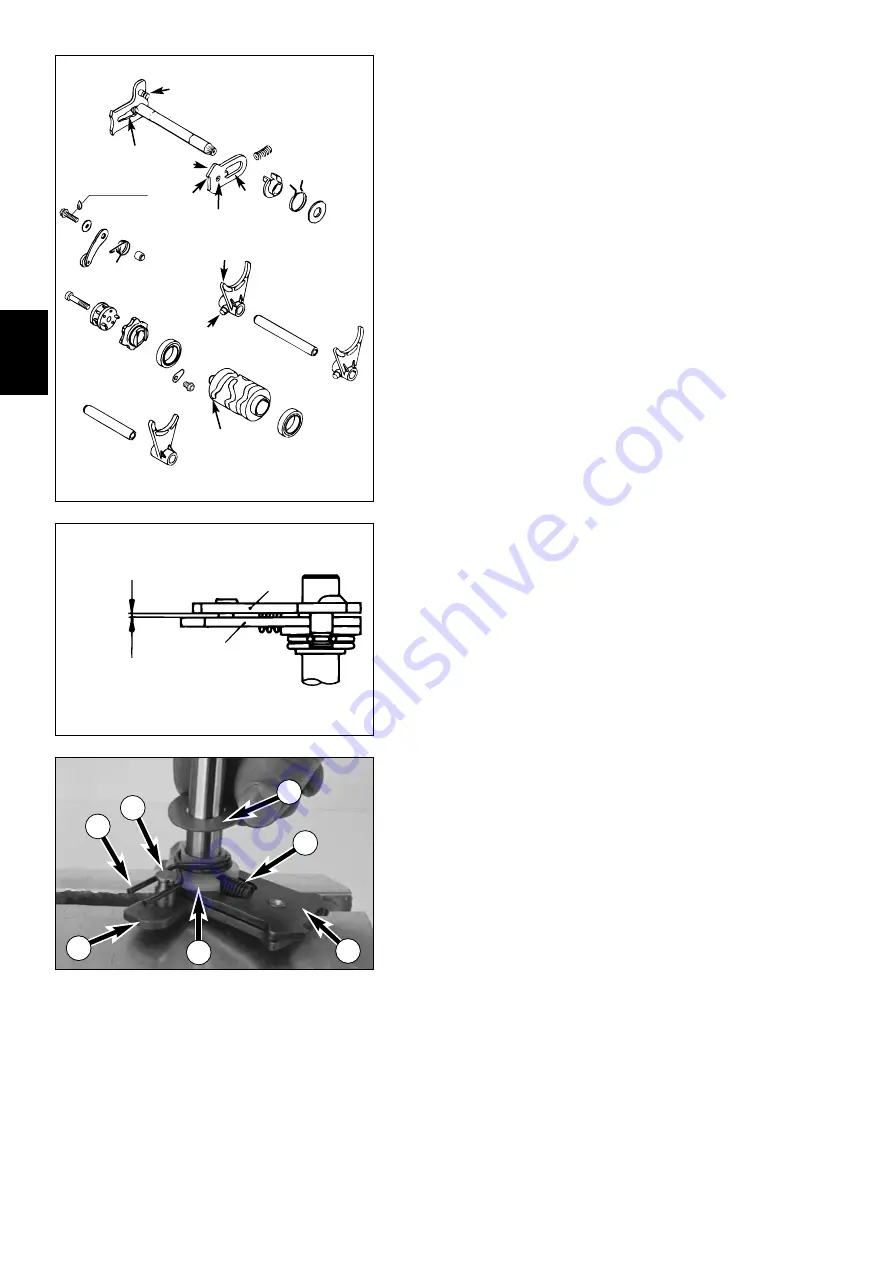

4.18 Shift mechanism

S

HIFT FORKS

1

Check shift fork blades

A

and shift roller driving pin

B

for signs of wear.

S

HIFT ROLLER

2

Check shift grooves

C

for wear.

Check position of shift roller in grooved ball bearings

bl

.

S

LIDE PLATE

3

Check slide plate at meshing points

D

for wear.

Check return surface

E

for wear (renew, if strongly notched).

Check that guide pin

G

is securely fixed and check for wear.

S

LIDING GUIDES

F

Check sliding guides (excess between guide pin and shift quadrant not to be more

than 0.7 mm / 0.03 in).

B

ALL BEARINGS

bl

Check ball bearings for easy movement.

S

HIFT MECHANISM

Assemble shift mechanism (see below) and check free play between slide plate

3

and shift quadrant

4

. Free play should be 0.4 - 0.8 mm (0.016 - 0.032 in).

4.19 Preassembly of shift shaft

– Fix shift shaft in vice at shorter end (use covered clamps).

– Mount slidie plate

3

with guide pins downwards, hook guide pins into shift qua-

drant

4

.

– Mount pressure spring

6

.

– Slide on spring guide

7

, slide on return spring

8

with offset end upwards over

the spring guide and lift offset end over bolt

9

(see illustration).

– Mount the stop disc

bk

(14x30x1 mm).

4

0

3

4

6

7

8

9

10

1

1

1

A

B

2

C

3

D

4

E

G

6

7

8

9

10

11

11

LOCTITE 242

F

F

Содержание 250 1998

Страница 9: ... Notices ...

Страница 39: ... Notices ...

Страница 43: ... Notices ...

Страница 44: ...7 1 7 0 Trouble shooting Cap Component Component unit Page 7 1 Trouble shooting 7 2 ...

Страница 47: ... Notices ...

Страница 54: ......

Страница 55: ......

Страница 56: ......

Страница 57: ......

Страница 58: ......