10

6.4.

Functioning principle

Description

The valve consists mainly of a body (100), operating shaft (213), shaft

(210), disc (550) and different types of seats (144).

Disc--shaft connection:

The operating shaft (213) is connected to

the disc (550) by grooved pins, splines or taper pins.

Shaft seal area:

MT II type: realized by elastomer O--Ring (412) fitted into a gasket

holder (559). Fire safety is achieved by a graphite packing (01--48)

tightened by the gasket holder (559), screws (901.1) and washers (554).

150 type: realized by a sealing packing (01--48) tightened by a packing

gland (452) studs (902) and nuts (920).

TBT II type: realized by elastomer O--Ring (412) fitted into a gasket

holder (559). Fire safety is achieved by a graphite packing (01--48)

tightened by the gasket holder (559), screws (901.1) and washers

(554). Lip seal ring (415.1) tightened by the gasket holder (559), the

sealing packing (01--48), screws (901.1) and washers (554).

Flow seal area:

MT II types (Wafer, Lug and Flanged Bodies for DN

10” Class 150

and DN

8” Class 300: the seat (144) is tightened in the body (100) by

a tightening flange (72--3) which maintained by radial screws (904) or

axial screws (901).

TBT II and MT II flanged types for DN > 10” Class 150 and DN > 8”

Class 300: the seat (144) is tightened in the body (100) by a centring

flange (72--2) maintained by a tightening flange (72--3) which is held in

place by inner ring (932) and axial screws (901.3).

150 type: the seat (144) is tightened in the body (100) by a tightening

flange (72--3) which is held in place by an inner ring 932 or by 4 screws

(914).

Bonnet seal area:

TBT II types: It is made by a metallic seal (41--2) tightened by the

extension (13--21), studs (902) and nuts (920).

The compression of the seating disc edge out of the seat is achieved

by double eccentric kinematics.

The axis of the shafts and disc is offset to valve axis and eccentric to

pipe axis.

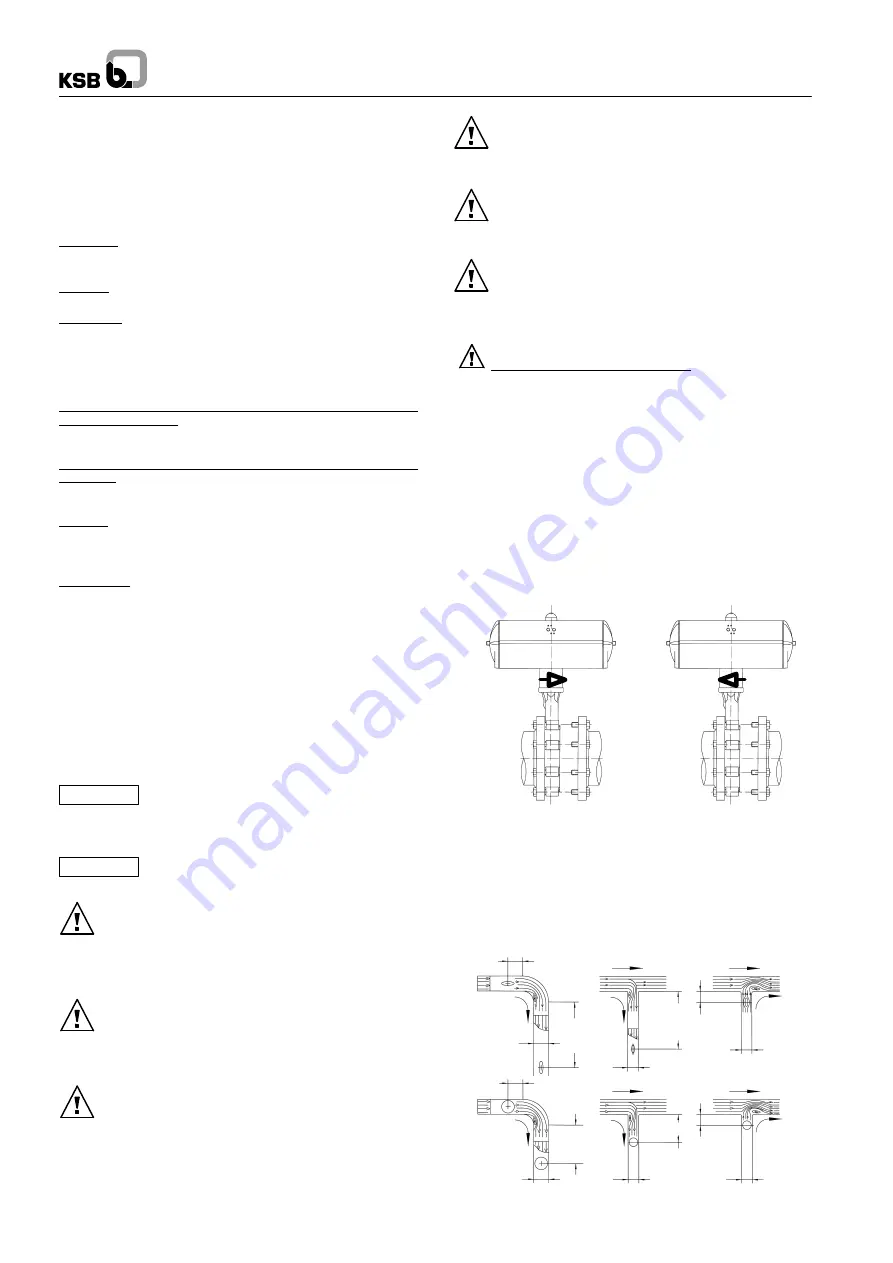

Operation:

The valves are quarter--turn operated manually by

handles or gear box or hydraulic, pneumatic and electric actuators

bolted on the valve top plate (as per ISO 5211 standard).

7.

Installation

7.1.

General

ATTENTION To avoid leakage, deformation or rupture of the body,

the piping should be laid out in such a way that no thrust or bending

forces act on the valve bodies (100) when they are installed and

operational.

ATTENTION The sealing faces of the flanges must be clean and

undamaged.

It is mandatory to add gaskets between body and piping

flanges. To insert the valve between flanges, pull apart the two pipes

flanges to obtain sufficient clearance between valves flanges and

piping flanges. All holes provided in the flanges must be used for the

flange connection (does not apply for buttweld type valves).

lf construction work is still in progress, non--mounted valves

must be protected against dust, sand and building material etc.(cover

with suitable means).

Do not use valve handles and gear handwheels as footholds!

Valves and pipes used for high (> 60

°

C) or low (< 0

°

C)

temperatures must either be fitted with a protective insulation, or there

must be warning signs fitted showing that it is dangerous to touch

these valves.

lf a valve is used as end-valve in a pipe, this valve should be

protected against unauthorized or unintentional opening to prevent

personal injury or damage to property.

To guarantee a good operation of the valves at temperatures

< 0

°

C it is necessary to eliminate all the water (steam or liquid) inside

the piping to avoid freezing at the seat gasket or lower shaft level.

For the DANAIS TBT II Buttweld, the protections inside the

valve must be kept until the end of the welding and cleaning

operations. These protections must be removed before operation.

DANAÏS 150 body type 4 (lug type):

Specific instructions for end of line use:

(see figure 1)

-- it is

mandatory

to insert the valve between flanges in the preferential

direction, pressure upstream.

-- tighten the tightening flange 72--3 against the piping flange.

Specific instructions for downstream dismantling:

Check the position of the valve on the piping (direction of the arrow on

the yoke)

In case of piping dismantling downstream side (see figure 1):

-- make sure that the valve is in the closed position

-- remove the piping downstream side.

In case of piping dismantling upstream side (see figure 2):

-- depressurize and drain offf the downstream piping

-- remove the piping upstream side.

Figure 1

Figure 2

It is advised to put in place a blind flange for safety reasons.

7.2.

Installation conditions

7.2.1.

Recommended minimum distances between

the position of the valve and of the T--piece or

elbow.

Ø

1

Ø

Ø

Ø

1

Ø

Ø

2--3

Ø

Ø

Ø

1

Ø

1

Ø

2--3

Ø

5--6

Ø

2--3

Ø

Also valid for valve placed at pump discharge