INSTALLATION

3

23

OPTIMASS 7000

www.krohne.com

10/2015 - 4001016303 - MA OPTIMASS 7000 R03 en

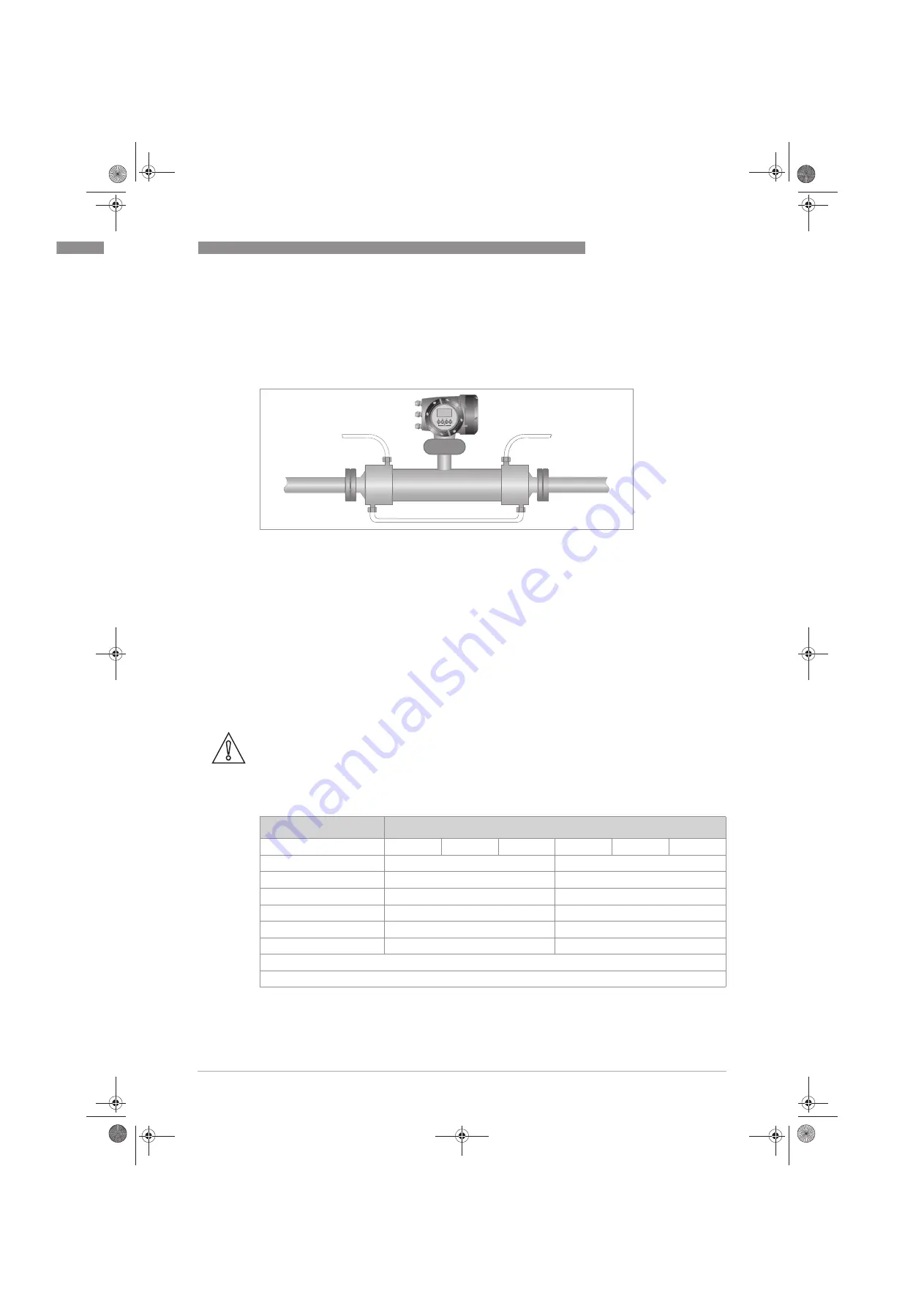

Factory fitted heating jacket

Factory fitted heating jacket

Factory fitted heating jacket

Factory fitted heating jacket

If the meter has been ordered with a heating jacket, it will be supplied with NPT, Ermeto or

flange connections.

Connecting / using the heating jacket

•

Use reinforced flexible hoses to connect the heating jacket to the heat source.

•

The heating jacket material is 316L but the heating medium is also in contact with the outer

cylinder, which might be a lower grade Stainless Steel.

•

Suitable heating mediums are steam or hot oil. Avoid the use of heating mediums that can

cause crevice corrosion in Stainless Steel.

•

Where liquid is being used, set up the pipe configuration so that air can be vented from the

system.

•

Where steam is being used, set up the pipe configuration so that condensation can be drained

off.

•

Heat the jacket to working temperature before flowing the process fluid through the meter.

Heating times

CAUTION!

The maximum heating jacket pressure and temperature is 10 barg at 150

°

C / 145 psig at 302

°

F

for Titanium measuring tubes and 10 barg at 100

°

C / 145 psig at 212

°

C for Stainless Steel,

Hasteloy and Tantalum measuring tubes.

Temperature [

°

C /

°

F]

1

Time [minutes] for Titanium measuring tube

10

15

25

40

50

80

40 / 104

30

90

60 / 140

80

160

80 / 176

120

330

100 / 212

190

495

120 / 248

270

735

140 / 284

480

1320

1

Measured at the centre of the measuring tube.

MA_OPTIMASS_7000_en_151026_4001016303_R03.book Page 23 Monday, October 26, 2015 4:44 PM